Brief introduction of the function of vacuum casting mold

To perfect the defects exists in the design of plastic product, we can make samples of the product and improve its performance by testing the samples. Small-batch samples manufacturing methods like 3D printing, vacuum casting mold, and simple injection mold are the most practical technologies in the project. Let us focus on the vacuum casting mold today.

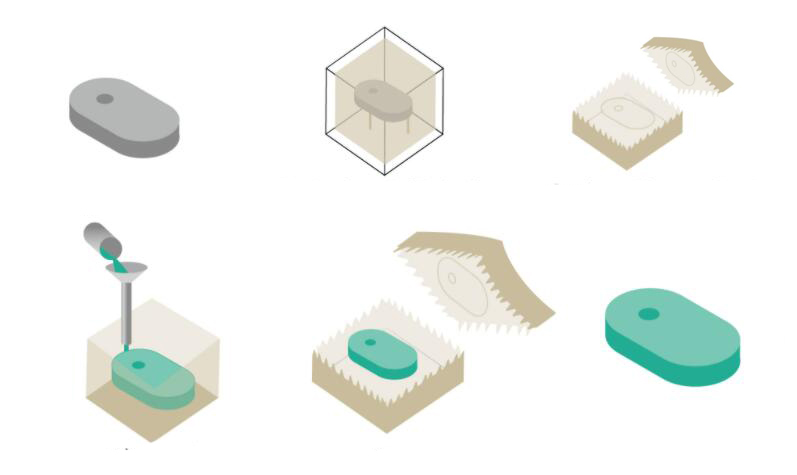

Vacuum casting mold is a simple technology that to use product prototypes to make silicone molds in a vacuum environment, and use ABS, polyurethane, and other material to form a silicone mold with a cavity. You can inject the melt into the cavity and get the target plastic parts which has the same functionality as injection molded parts after cooling.

The vacuum casting mold has the advantages of low-cost, short production cycle, which will be the best solution of new product development. Compared with 3D printing, the performance of the samples is better, and the details of the sample are closer to the molded parts. For small batch of samples manufacturing, vacuum casting mold will be a good choice, especially for products that require functional verification and dimensional testing.

Shanghai Future Mould is a professional injection mold factory. To meet the design rectify target, we also provide customers with professional 3D printing and vacuum casting mold services, which greatly help the process of product development.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds