Cavity number setting of injection mold

As an industrial foundation, injection parts are everywhere in your life, and it has a wide range of application scenes, such as automotive, electronic, medical, etc.

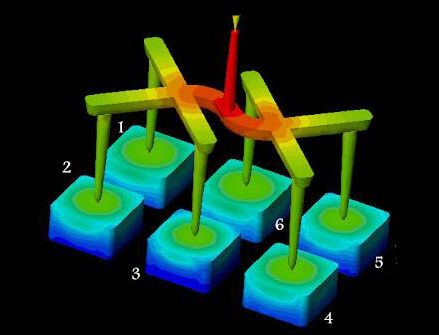

The injection molds worked as a mechanical tool for the production of plastic products, which has an important situation in the plastic industry. For small-batch products or single cavity mold, we often apply a single cavity design on the injection mold to meet their requirements on production. But for others, it requires a multiple cavity design to meet the quantity target in the production.

The multi-cavity mold has the advantages of high-speed, low-cost, energy-saving, however, it is difficult for us to locate which cavity causes such defects when we meet low-quality parts. For this issue, we assign each cavity with specific numbers. When we meet defects, we can quickly find out where the defect is from, from which cavity, and we will know its reason for reviewing this cavity. In this way, we can greatly save time and costs on finding the defects.

Some notes need to be mentioned on cavity number setting: 1. It should not affect the structure of the product. 2. It must not influence the appearance of the plastic parts. 3. It is not allowed to damage the mold and its cavity. 4. Make sure that the cavity number is visible.

Shanghai Future Mould is a professional injection mold factory, our factory is capable of producing large-size and multi-cavity molds. And reasonable cavity number can be set before production for each cavity to ensure the efficiency of subsequent production.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds