Cold runner and hot runner molds

At present, there are two different types of injection molds known as the cold runner mold and the hot runner mold. The runner is the most basic part of the injection mold, and it is the channel through which the melted plastic enters the cavity from the barrel. As the name suggests, it is not hard to figure out that the main difference between these two types of molds is in the structure and temperature of the mold.

1. Cold runner mold.

In the cold runner mold, the product is cooled by cooling water of the cooling system in the mold, compared with the hot runner mold, the biggest disadvantages of the cold runner mold are that the cold runner mold produces lots of waste, and some thin structure product, the melted material might cool off before full the cavity.

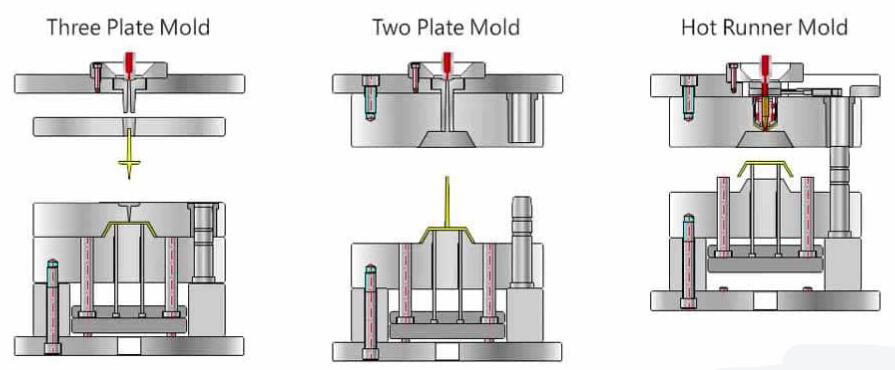

There are two plate mold and three plate mold, the main difference between these two molds is the structure of the mold. The advantage of the three plate mold is that the gate can be set at any position on the outer surface of the product, which can improve the gate options in the design.

2. Hot runner mold

In the hot runner mold, the mold and the runner are heated by the hot runner device, and the temperature is generally higher that the melting point of the plastic materials. In the hot runner mold, there is little product waste, and the fluidity of the melted plastic in the cavity is good, and both the structure and the appearance of the product will be in a high level.

The biggest disadvantages of the hot runner mold are that the manufacture cost of the mod is high, and the hot runner needs regular maintenance. When needs color changes, it is difficult to clean the melted material stuck inside the runner.

Cold runner molds are still the first choice for some companies due to their reliability and efficiency. However, for companies with higher product quality requirement, hot runner is the key to reach their demands. Shanghai Future Mould is an enterprise delicated to high-quality mold processing, we can provide customer with the best mold processing suggestions by their needs. Welcome to consult.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds