Do you know how to choose multi-cavity molds and family molds?

Injection mold is a tool used to produce plastic parts, and it is also known as the basis of modern industry. In the mold manufacture process, one plastic product corresponds to one set of mold, and if you need multiple plastic products, we can adopt a multi-cavity mold. So how to determine the suitable mold structure based on your needs?

1. Multi-cavity mold

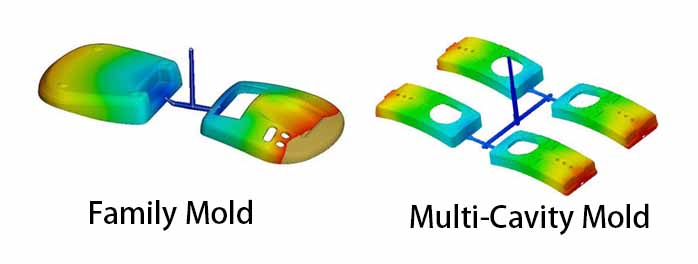

Multi-cavity mold refers to a mold containing two or more cavities of the same part in the structure. Multi-cavity molds can produce more plastic parts in one injection cycle, which is more suitable for plastic products that require high-volume production.

Advantages of multi-cavity molds:

1. Short lead time

2. Lower cost of molds and products

3. High efficiency.

1. Family mold

Family mold has multiple cavities also, but the difference between multi-cavity mold is the product shape. Family mold is more suitable for injection products with similar sizes in different shapes.

Advantages of family mold:

1. It can produce several plastic parts at one injection cycle.

2. Suitable for small batch products

3. There are switches between each cavity for individual control, making the mass production more flexible.

Many tips need to be mentioned in the process of family molds:

1. Different products need to use the same material with the same color.

2. The size and volume of the products are similar.

3. Choose a suitable runner system according to product size, etc.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds