Flame-retardant plastic materials

Flame retardant plastic materials are a special type of plastic material whose main purpose is to meet the fire-resistant requirements of plastic and rubber products. Flame-retardant plastic materials are processed and modified by combining and modifying multiple flame-retardant components based on flame retardants.

Common flame-retardant materials and their mechanism:

1. Heat absorption. This type of flame retardant material absorbs more heat before reaching the thermal decomposition temperature by increasing its heat capacity, thereby achieving fire retardant performance.

2. coverage effect. The flame retardant can form a glassy or stable foam covering layer at high temperatures, which achieves flame retardant performance by isolating oxygen.

3. inhibition of chain reaction. According to the chain reaction theory of combustion, free radicals are required to sustain combustion. Flame retardants can capture free radicals in the combustion reaction, thereby preventing the spread of fire.

The applications of flame-retardant plastic material are growing, and its main advantages include:

1. improved fire safety.

2. Reduced fire risk.

3. protection of personnel and property safety.

4. compliance with industry standards.

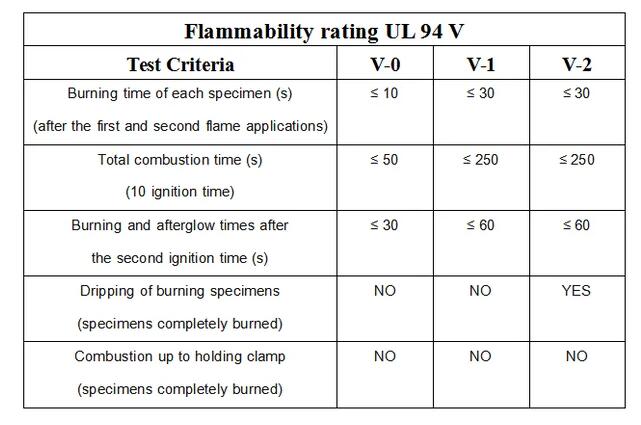

UL94 flammability rating is the most widely used flammability performance standard for plastic materials, mainly used to evaluate the ability of materials to extinguish after being ignited.

Plastic flame retardant grade: HB, V-2, V-1, V-0, 5VB to 5VA.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds