How many injection mold gate forms do you know?

The injection mold gate, also known as the feed port, is a short channel connecting the runner and the mold cavity. The injection mold gate is also a key part of the feeding system.

The main functions of the gate are:

1. After the cavity is filled, the melted plastic first condenses at the gate to prevent backflow.

2. It is easy to remove the condensate of the feeding system at the gate.

When the melted plastic passes through the gate, the shear rate is increasing, and the internal friction is increasing which causes the temperature of the plastic to increase, the viscosity decreases. If the gate size is too small, the pressure loss will increase, the condensate will accelerate, and seriously, it may cause the spraying phenomenon, which affects the quality of the plastic parts.

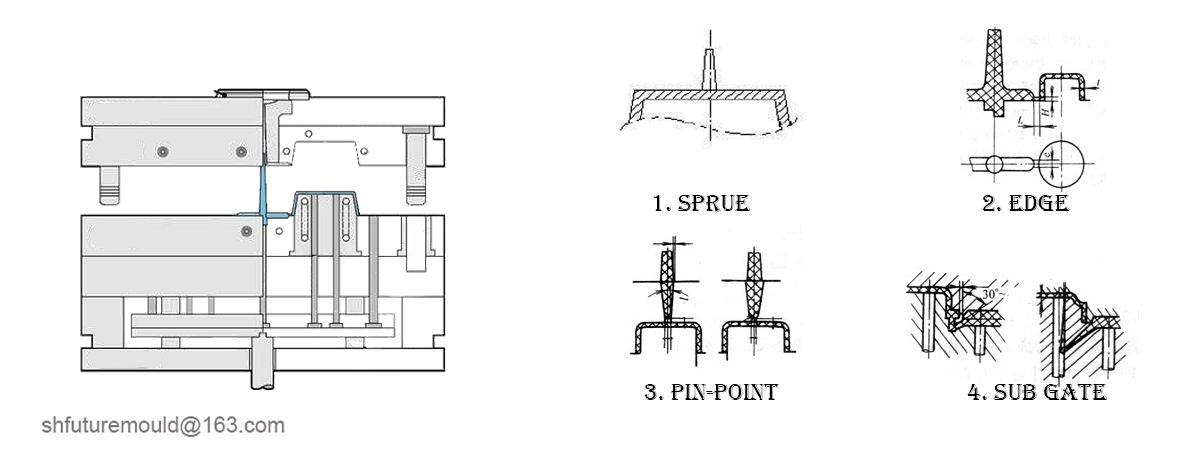

The main forms of injection mold gate:

1. Sprue gate

The sprue gates are also called center gates. This gate has low flow resistance and fast feeding speed in the injection process, and it is mainly used in single-cavity molds to form larger and more complex plastic parts. This gate is suitable for all kinds of materials, especially the materials with high viscosity and poor fluidity. When forming thin and flat parts with a sprue gate, it is easier to generate bending and deformation of the plastic parts, and there are will be obvious traces on the surface of the parts, so in the mold design stage, the mold designer should set a suitable sprue gate to avoid defects.

2. Edge gate

The cross-section of the edge gate is rectangular, and generally set up on the parting surface, and feeding the material from the side of the plastic. The mold designer can choose the right place to set up the side gate to achieve a more complex surface, especially for multi-cavity molds.

3. Point gate

The point gate is also called the pin-point gate, it is a mold gate with a small size, and the shear rate of the plastic from here is higher.

This type of gate is being widely used in shell-like plastic parts, and in the demolding process, it can be pulled off from the gate side without any external force.

4. Sub gate

The sub gate is derived from point gate, the point gate is for three plate mold, and the sub gate is for two plate mold. The sub gate structure simplifies the mold structure.

The sub gate is set in an inner part or the outside of the plastic part, which will not affect the appearance of the plastic part, also it needs a strong thrust to pull the plastic parts out of the mold, so this gate is not suitable for some strong plastic.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds