How many types of injection molding do you know?

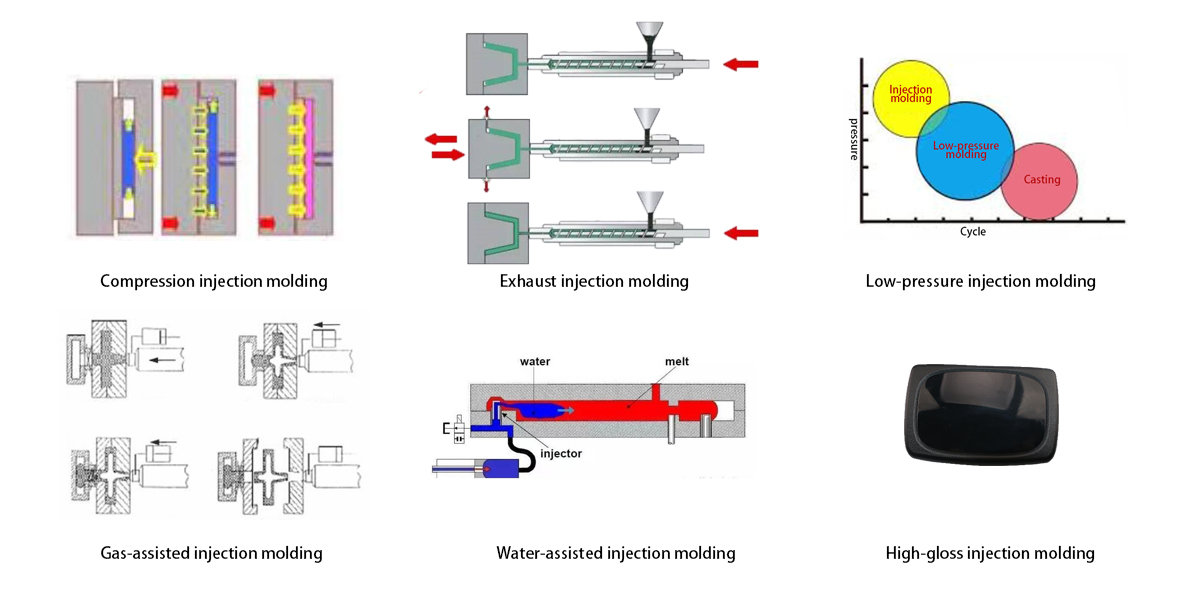

1. Compression injection molding

Compression injection molding is a traditional injection molding method, and its advantages are: it can increase the flow length ratio of plastic products(plastic flow length ratio refers to the ratio of the flow length of the melted plastic to the wall thickness). In the injection molding process, it requires lower clamping force and injection pressure, and it can effectively reduce the internal stress of the product and improve the processing efficiency.

2. Exhaust injection molding

The purpose of the exhaust in the injection molding process is to discharge the volatile gases generated during the polymerization and solidification of plastic particles. If these gases remain in the cavity, it will bring such defects as bubbles and short shots.

3. Low-pressure injection molding

Low-pressure injection molding is a packaging process that uses a low injection pressure to inject hot melted material into the cavity and make sure the melted plastic solidifies quickly.

4. Gas-assisted injection molding

Gas-assisted injection molding includes an injection step, inflation stage, pressure holding stage, pressure reduction stage, and demolding stage. The composition of the gas-assisted molding device includes a gas generator, a gas control unit, etc.

5. Water-assisted injection molding

Water-assisted injection molding technology is an injection molding process that a portion of melted material will inject into the cavity and high-pressure water will inject into the cavity through the equipment afterward. Compared with gas-assisted molding, the advantages of water-assisted molding include high product quality and time-saving.

6. High-gloss injection molding

The process of high-gloss injection molding is to use high-temperature water steam to heat the mold surface before injection molding, so the surface temperature of the molding cavity reaches the glass transition temperature of the plastic particles and then the plasticized melted material will inject into the cavity for shaping.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds