How much do you know about the PBT material?

PBT is one of the strongest thermoplastic materials. It is a semi-crystalline material with good chemical stability, mechanical strength, electrical insulation, and thermal stability.

The properties of PBT materials are as follows:

1. The melting point and deformation temperature of PBT material are lower than other materials such as PET.

2. The viscosity of PBT material is very low, and its molding cycle is relatively short in the injection molding process.

3. The moisture absorption properties of PBT materials are weak.

4. PBT material has a fast crystallization speed, and it is easy to cause deformation problems due to the unstable cooling during the injection molding process.

5. The shrinkage rate of the PBT material is between 1.5-2.8%

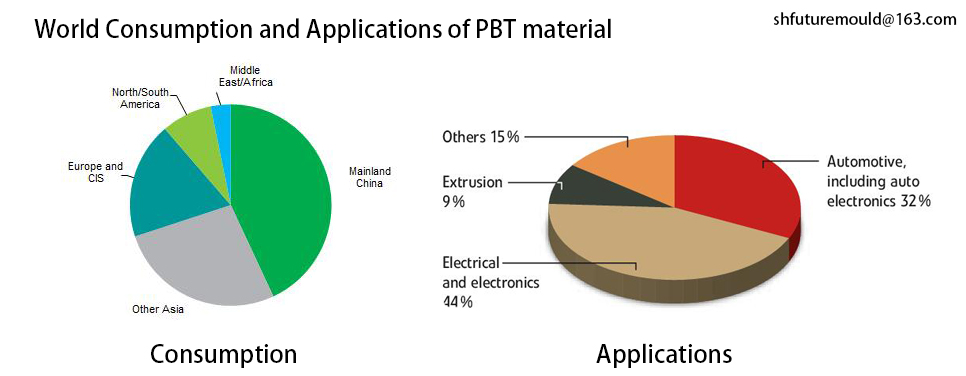

Main application areas of PBT material

1. Automotive industry

Most of the PBT materials used in the automotive industry are compliant materials, mainly compliant alloy material formed by PBT and PC materials, which can be used as the raw material for automotive bumpers. PBT materials can also work as the raw material for producing automotive wheel covers, door trims.

2. Electrical industry

PBT material has strong electrical insulation properties and can be used as raw materials for making electrical appliances. Good electrical insulation can provide safe environments for related components.

3. Others

PBT material can mix with other materials to form composite materials, such as mixing with glass fiber to produce electrical cases and mixing with PC to produce plastic blades.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds