How to avoid the density bubble in the injection molding process?

The defects in the injection molding process have always been considered to be the main factors affecting the quality of the product. To solve these defects, it needs analyze the mold structure to injection machine settings, etc. and eliminating the modifications one by one to achieve quality improvement effectively.

Bubbles are one of the injection molding defects, which will affect the structure and appearance of plastic products. During the injection molding process, there are three main reasons for the occurrence of bubbles.

1. Improper control of molding

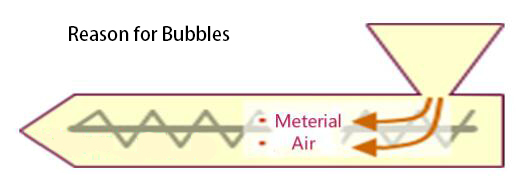

When the injection machine is under high speed, the gas in the mold failed to discharge from the cavity in time, the extra gas will stay in the cavity and melted plastic, it will cause bubbles in the injection. In this case, we should reduce the speed and adjust to a reasonable speed to ensure the exhaust efficiency inside the mold. If the speed drops too much and the injection pressure is too low, it is difficult to discharge the gas in the melted plastic, which is easy to produce other types of defects. You can adjust the injection and holding time, and improve the cooling conditions to avoid the formation of bubbles and density bubbles.

In general, we need to control the melting temperature slightly lower, and the mold temperature higher. It is not easy to generate a large amount of gas and to produce shrinkage holes. When controlling the temperature of the barrel, the temperature in the feeding stage should not be too high, otherwise, it will cause the backflow of the material to cause bubbles on the products.

2. Mold structure

If the gate position of the mold is incorrect and the cross-section is too small, the main channel and the shunt channel are long and narrow, which can easily cause poor exhaust of the mold and bubbles in the injection processing. First, it is necessary to determine whether the mold structure is the main reason of the bubbles, and then, focusing on the specific situation, adjust the structure parameters of the mold, especially the gate position.

3. Raw material

Some of the raw material can generate gas in the injection process, the main solution of this condition is:

1. Pre-dry the raw material to release the gas inside the raw material.

2. To reduce the temperature of the material in the injection process to avoid gas.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds