How to avoid the sharp corner in injection mold?

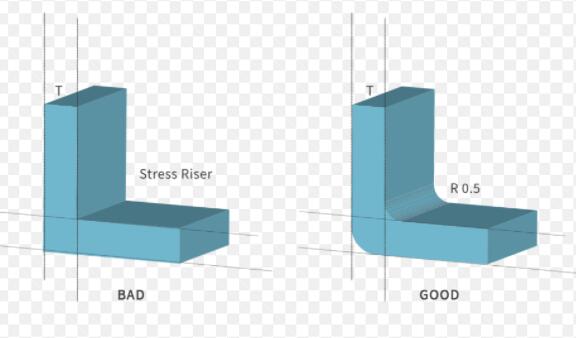

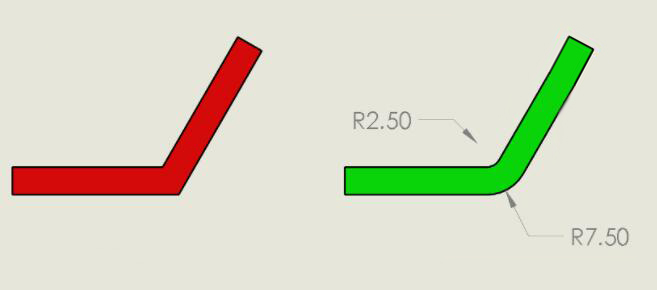

The sharp corner in the molds means that when the angle formed by the two or three sides of a plastic product is less than 120°, internal stress will be generated at the sharp corner. This sharp corner part where the internal stress is concentrated is the weakest part of the product. So, how to avoid the sharp corner and improve the plastic parts design?

In the molding process, the first consideration in the design is to remove the internal stress as much as possible, it is better not to adopt sharp corner designs, and make sure the product will not be damaged due to the excessive internal stress.

In the mold design, we can use round corner designs to replace the sharp corner, especially for the parts that use plastic material with poor fluidity. The round corner design can improve the efficiency of the molding process also increase the structural strength of the products. The round corner design also has advantages in mold processing, the corresponded design of the round corner on the mold will enhance the performance of the mold and extend the service life of the mold as well.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds