How to choose the right injection molding material

In most of the custom orders we received, the common product materials are ABS, PP, PA66, etc. Of course, some customers choose the product materials themselves reasonably, but some will ask us to help them to choose the material. No matter what the case is, we will not ignore the step of fully consider whether the material is suitable, and choose the most suitable and cost-effective plastic material for customers as much as possible. The characteristics and applications of these common materials are described below.

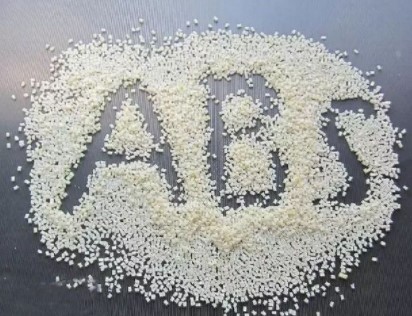

ABS

ABS

Acrylonitrile butadiene styrene copolymer (ABS), commonly known as super undegradable rubber, has excellent toughness, strength, impact resistance, and temperature resistance. The general injection temperature is 180 ℃ ~ 240 ℃.

The color of non-processed ABS is opaque and ivory, but the product can show a variety of colors. Any thermoplastic processing method can be used to process ABS materials, because it easily adheres to itself, similar plastic and metal coatings, so it is very suitable for a variety of different products. Among the products we produced, like auto gear lever cover, car air conditioning vents, electrical socket components, household mop components, water pipe connections, fruit knife handle components, etc. , all use ABS material. However, ABS has poor chemical resistance, so it should not be used in applications that require electrical insulation or UV resistance.

PP

Polypropylene is known as chemical resistance, elasticity and toughness, fatigue resistance, insulation properties, and transmittance. Its’ obvious melting point is about 173 ℃. Generally, the injection temperature is 190 ° C ~ 240 ° C.

The surface of PP is relatively slippery and it performs well in low friction applications. It is susceptible to degradation by ultraviolet radiation, so it can be used as an environmentally friendly material. We have PP products such as mobile phone casings, air filter covers, drawing stencils for kids, food preservation boxes, laboratory funnels, etc. However, flammable and brittle at low temperatures are two main problems in the application of PP in the automotive field. Therefore, it is necessary to add suitable additives.

PA66

Polyamide 66 has the characteristics of high strength, good toughness, small friction coefficient, and self-lubricity, high water absorption, and thermal degradation. It also has high-temperature sensitivity and shear rate sensitivity, so it is commonly used in automotive sensors. However, the processing and forming process is not easy to control. When designing the product, the influence of its hygroscopicity on geometric stability must be considered. Only by fully understanding the characteristics of the materials can we better choose the right material for production.

Other plastic materials related queries, welcome to contact us for more information.