How to control the color difference of injection products?

The color difference is a common defect in the injection molding process, and it is common to meet the scrap problem because of the color difference. Many factors cause the color difference in the injection process, including raw materials, color masterbatches, injection molding machines, and injection molds. In the injection molding process, we control the color difference from five aspects, they are:

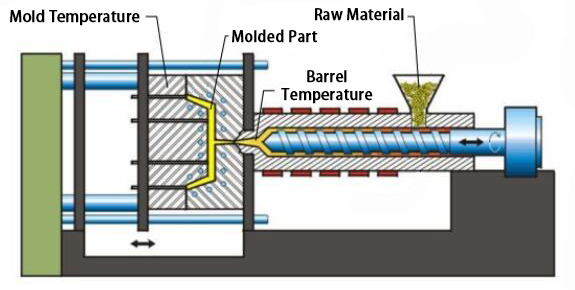

1. Injection molding machine and injection molds

It is necessary to select an injection molding machine with the same injection capacity. If the injection molding machine has material cold corners, it is better to replace the injection molding machine. For mold gating systems, we can repair the corresponding parts of the mold.

2. Raw material and masterbatch

Controlling raw materials is a key part of solving the color difference in the molding process. Generally, the raw materials used in injection molding are purchased from suppliers. The injection molding factory should conduct a strict inspection on the raw materials and color masterbatches and use the same manufacturer and the same brand of raw materials and color masterbatches as much as possible to avoid color differences from different suppliers.

3. Uneven mixing of color masterbatch and raw material

Before the injection molding process, the masterbatch and material should be well mixed to avoid the separation of raw material and masterbatch caused by static electricity. We can use a manual auxiliary method to mix the color masterbatch and raw materials. Regular cleaning of the feeder is also one of the necessary ways to control the color differences.

4. Barrel temperature

The drastic change of barrel temperature can also cause a color difference in the product. The color difference caused by temperature changes is easy to judge. Generally, the temperature change of the barrel will also cause uneven plasticization.

5. Injection molding process

When adjusting the injection machine parameters, and do not change the set injection temperature and pressure, and it is also necessary to check the product color condition in the adjustments.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds