How to demold a product with threads?

Threaded products have always been one of the toughest types of injection products in production, especially in the demolding process, you need to design reasonable demolding methods for different thread structures to make sure that the product can be used normally after injection, so what are the demolding methods for threaded products?

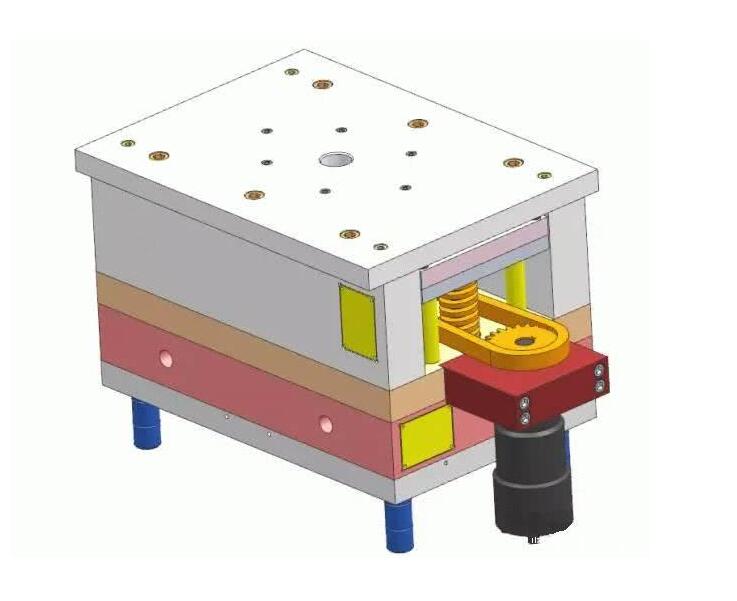

Rotary

The rotary method generally requires external forces to drive the demolding mechanism in the mold. The product and mold will be separated with the help of the rotary system. The rotary mechanism is a gear transmission system, and it saves manpower also improves efficiency.

Thread Slider

For the product with external thread, we adopt thread sliders structure mold. We can achieve the demolding by moving the slides and take the product out of the mold manual. This type of demolding method costs less.

Forced demolding.

When the thread teeth on the product are in the shape of arcs, we can remove the product directly by ejector plate, it will not bring much damage to the products.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds