How to identify the difference between the injection mold and prototype mold?

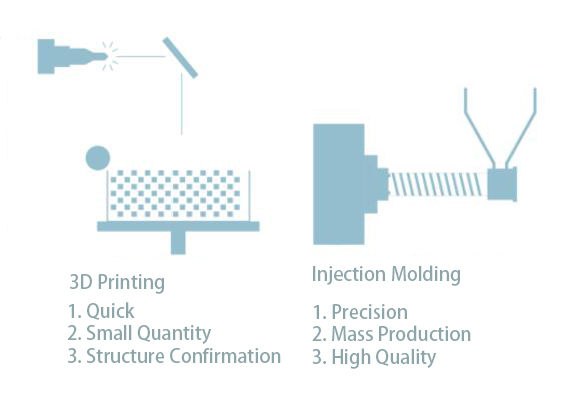

The prototype is a quick sample service. When designing a new plastic product, the designer cannot complete all the detailed and functional design of the product at one time. If we proceed with the mold manufacture of the first version of product design, we will waste abundant of manpower and costs once we meets some faults on the design. The advantages of the prototype are the short production cycle and simple production process. We can produce same prototype samples to verify and improve the design, therefore to short the design and production cycle.

The injection mold is a production tool that can produce parts with certain structure and dimension required. At present, there are many plastic parts produced by injection molds from all walks of our life. The function of prototype and injection mold are totally different, but they are also interdependent in the new projects. We can set the final design of the plastic parts with the support of a prototype sample, then go ahead with related mold design and manufacture, it will greatly shorten the molding cycle and production cost of the plastic parts.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds