How to prevent such risks when processing medical products?

For the medical industry and the pharmaceutical industry, safety issues have always been the most important parts. Throughout the production process, we must make sure that the product produced fully complies with the medical testing standard.

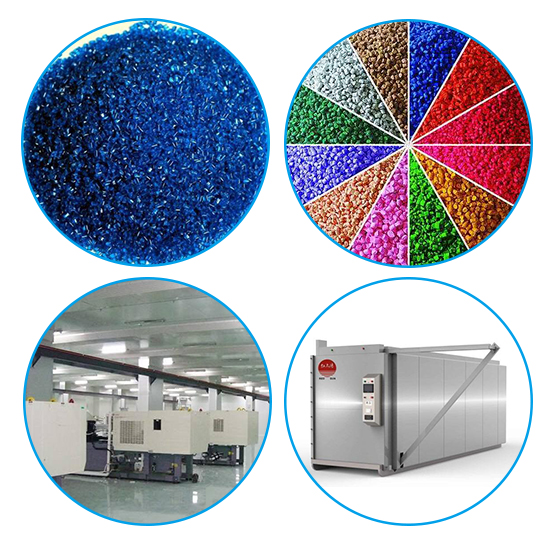

Medical grade materials

When we choose the materials, it is necessary to pick medical-grade material. The medical-grade materials have been tested by professional institutions and organizations, and are in line with the medical and health requirements of the products. At the same time, medical-grade materials have better physical and chemical properties than ordinary injection molding materials, and can better meet the requirements of products in terms of physical and chemical properties.

2. Production and processing

All medical-related products must meet medical device regulations. Injection molding is the most complex and changeable part of the entire project. It is necessary to ensure that each batch of raw material meets the standard and has the same physical and chemical properties.

3. Masterbatch and additives

To reach the safety standard, masterbatch and additives also need to undergo rigorous medical inspection. So far, many suppliers can provide medical-grade masterbatches and additives.

4. Disinfection

There are plenty of methods for doing disinfection, but we should apply suitable methods for different parts by their actual application environments.

Shanghai Future Mould is a medical injection mold processing factory with rich experience. It can process and produce medical-grade injection molds and perform medical-grade injection molding for customer needs.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds