How to process threads in plastic parts?

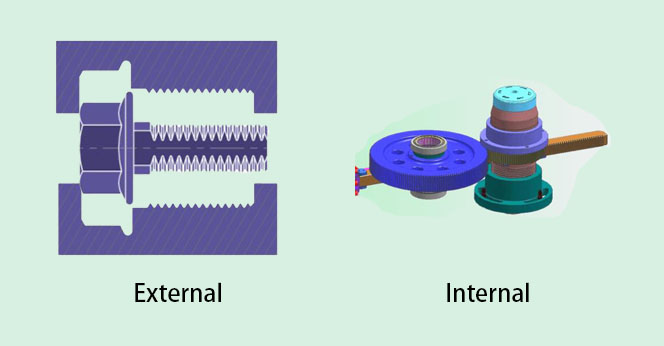

Just like the undercut, the thread is also one of the installation methods for plastic parts. By matching the threads on the two products, these two products can be quickly combined. Also, we can divide the threads into external and internal thread. As literally, the external thread is the thread on the outside of the product, and the thread inside the product we called internal thread.

For these two types of threads, we can process them with different methods.

1. External thread

The external thread is located on the outside of the product, we can use two sliders to forming the thread section.

2. Internal thread

The internal thread is inside the produce, and the demolding direction of the mold will be obstructed by the thread, which means that the product cannot be directly demolded from mold. For this issue, we have two solutions to complete the demolding without affecting the product quality.

Manual demolding is mainly suitable for the products with less demand, which can simplify the structure of the mold and reduce the costs of the mold. In the production, several sets of inserts can be made for improving the efficiency of the production.

On the contrary, rotary demolding suits for the product which has large demands in production. The products can be ejected from the mold through the rotation of the motor. This type of mold has a complicated structure and a higher manufacturing cost. As to which method to choose, it needs to be decided by the actual situation.

Shanghai Future Mould is a professional injection mould manufacturer. We have rich experience in threaded product processing, and can provide customers with the most economical and reasonable structure solutions by their needs.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds