What are the difference between the two color mold and insert mold?

1. The advantages of double color molding

The double color molding can convert resins with different characteristics and colors into a single product through a double-color injection machine, which can shorten the molding cycle and save production cost and can improve the appearance of the product.

The double injection mold has high-quality stability, short molding cycle, and lower consumption of the resins.

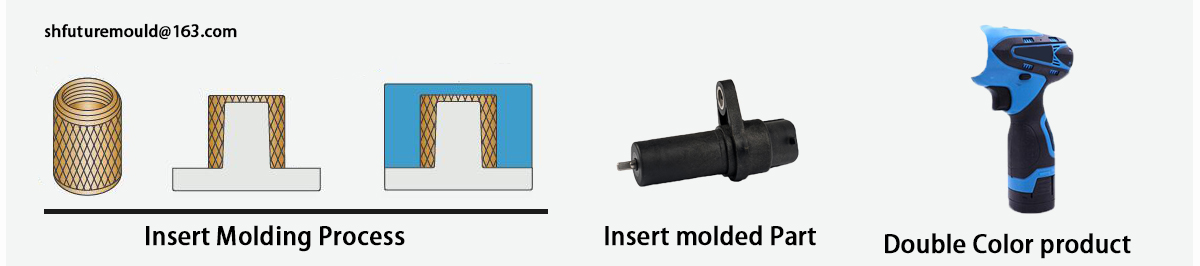

2. The forming principle of double injection mold

The double injection mold can form two resins with different colors and characteristics at one time, and the two sets of injection units and nozzles in the double-color machine are independent, so the colors of the finished product will not be mixed. The biggest difference between the double-color injection machine and the normal injection machine is the design of the movable template.

3. The characteristic of double color molding product

1. The double-color injection machine consists of two sets of injection devices with the same structural specification. The nozzles have a special structure, and in the injection process, the melted material temperature and injection pressure in the injection device should be the same, and the process parameter changes in the two devices should be the same too.

2. Compared with normal injection products, the double color molding products use higher parameter values of the melting temperature and injection pressure. The main reason is that the flow channel of the double injection mold is longer, the structure is more complicated, and the resistance is larger.

3. In the double color molding process, it is better to use the raw material with good thermal stability and low viscosity to avoid decomposition due to high temperature in the flow channel.

4. To make the two different materials weld well in the cavity and ensure the molding quality of the product, it needs to adopt a higher melt temperature, a higher mold temperature, and a higher injection pressure.

4. The difference between double color molding and insert molding

1. The double injection mold is set on the same injection machine, using two resins with different characteristics or different colors, and molded in two times.

2. For insert molding, it has two sets of molds, and there is no need to use a special injection machine, and it just needs to take the first product out from the first mold, and put into another mold for secondary injection processing, then demolding to get the well-finish product.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds