How to solve the difficulty of demolding?

In the injection molding process, there are three main reasons for the difficulty of demolding: 1. complicate product structure; 2. Insufficient draft angle; 3. Poor surface treatment.

In the injection molding process, it is common to meet the quality problems caused by insufficient draft angle, so it is necessary to apply a demolding angle in the range of 1-2°. If the injection pressure of the machine is high, the product will stick to the mold cavity and will be hard to release by the demolding mechanism.

Some solutions on how to solve the difficulty of demolding:

1. Adjust the injection pressure and shorten the holding time of the injection molding machine.

2. Adjust the mold temperature and use mold release agents to assist( for products with high appearance requirements, do not use mold release agents for demolding to keep the high appearance of the product surface).

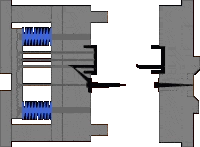

3. Improve the draft angle and adjust the ejection system of the injection mold.

4. It is necessary to design the demolding mechanism by the actual raw material of the products.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds