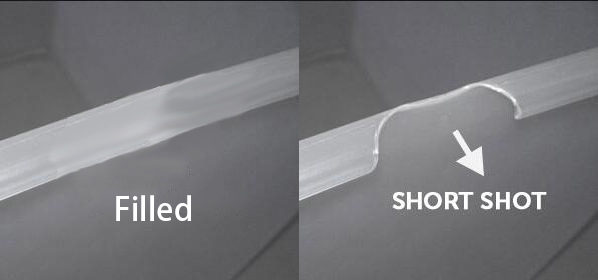

How to solve the short shot in the molding process?

The short shot refers to the defects that the melted plastic does not fill the mold cavity fully and make the product incomplete. This defect usually happens in the thin-walled area of the product and also the area away from the gate. For projects with higher product quality requirements, short shots are not allowed. Are there any methods to solve this problem?

Properly extend the injection time to ensure that the mold cavity is full.

Check the temperature of the barrel and injection mold, increase the temperature of the raw material and mold, and make sure the melt material can flow well from the nozzle to the cavity.

The injection pressure or injection speed is too low, no enough driving force to ensure the filling speed of the melt material.

Check whether the nozzle was blocked, and adjust the mold nozzle to ensure that all the melt material enters into the cavity.

Exhaust system. Check whether the exhaust system of the mold is working properly.

The setting of the runner and gate channel is unreasonable, mainly happens in multi-cavity mold.

Product structure, avoid the sharp corner in the design, or we can add other exhaust measures in the mold structure.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds