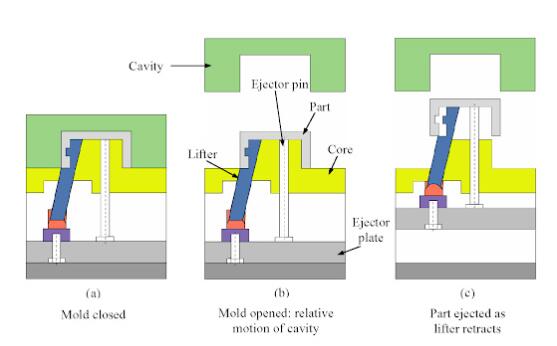

Injection Mold Lift Mechanism

An injection mold lift mechanism is a device used to eject plastic parts from an injection mold. It is a critical component of the injection molding process, as it ensures that the plastic parts are ejected cleanly and without damage.

There are two main types of injection mold lift mechanisms: mechanical and hydraulic. Mechanical lift mechanisms use a series of pins or rods to push the plastic parts out of the mold. Hydraulic lift mechanisms use a piston and cylinder to apply force to the plastic parts

The type of lift mechanism that is used depends on the size and complexity of the plastic part. For small, simple parts, a mechanical lift mechanism may be sufficient. However, for large or complex parts, a hydraulic lift mechanism is often required.

The design of an injection mold lift mechanism must take into account a number of factors, including the size and weight of the plastic part, the strength of the mold, and the force required to eject the part. The lift mechanism must also be designed to prevent damage to the plastic part during the ejection process.

Here are some of the benefits of using an injection mold lift mechanism:

Improved quality of plastic parts: A properly designed and implemented lift mechanism can help to prevent damage to plastic parts during the ejection process. This can lead to improved quality of the plastic parts, as well as reduced scrap rates.

Increased production efficiency: A well-designed lift mechanism can help to speed up the ejection process. This can lead to increased production efficiency and reduced cycle times.

Reduced labor costs: A lift mechanism can help to reduce the amount of manual labor required to eject plastic parts from the mold. This can lead to reduced labor costs and increased productivity.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds