Mold repair welding in the maintenance of injection mold

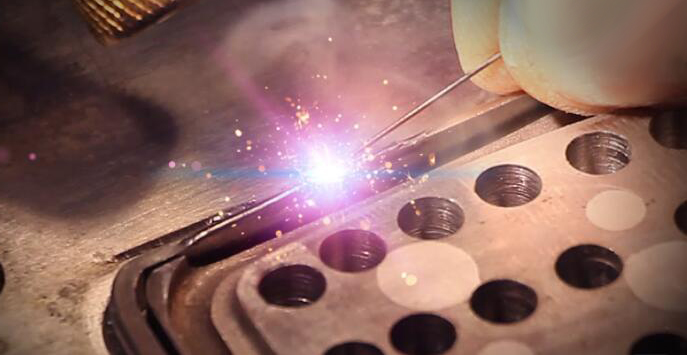

In the process of mold manufacturing or plastic parts mass production, it is easy to meet damage to the mold surface. Once you meet these issues, mold repair welding is the best option for maintenance. The mold repair welding is to fill the located site of the mold with appointed material by different kinds of welding methods, and then polishing the surface as the customer required.

There are four types of welding methods that are being used commonly: argon arc welding, laser welding, ion welding, and pulse welding. The ordinary welding process cannot meet the strength requirements of the mold process, so it is not one of the choices.

Among the four welding methods mentioned above, argon arc welding is the most popular choice. The working principle is to heat and melt the welding rods with argon gas for welding. If the product requires high transparency and texture performance, it is better to adopt laser welding as the repair solution.

Shanghai Future Mould is a professional mold manufacturing specializing in mold design and processing. We can provide customers with the design and processing of new molds and the maintenance of second-hand molds. Our company has a professional design team which can help you solve the structural issues as per your request.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds