The application of laser welding technology in the plastic mold industry

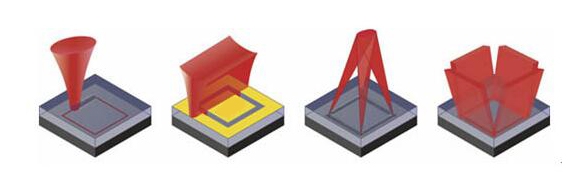

Laser welding technology is the latest technology that uses the heat generated by the laser beam to melt the plastic and then joint the plastic parts together. Laser welding is developing at a high speed now for the continuous decline in the cost of the equipment.

The popularity of laser welding technology also brings new possibilities to the molding industry. Some plastic parts with complex structures can be disassembled into several parts, and then joined them together with the support of laser welding. There are also some long-length plastic parts, the laser welding is now becoming an efficient solution, which is better than a complex mold structure.

Speaking of this, some people will question the stability of laser welding and whether it can meet the standard of industries requirements. The advantages of laser welding include its precision and safety. For the product with precision requirements, laser welding ensures the safety of the whole process and the integration of the plastic parts. Another advantage of laser welding is that it is easy to control. The intensity of the laser can be controlled by a computer, and we can arrange suitable intensity of the laser for different sizes of products to further achieve the optimal welding effect. Laser welding can greatly reduce the thermal stress of plastic products, can effectively alleviate the aging speed of plastic products, and improve the service life of products.

Shanghai Future Mould is a professional injection mold manufacturer, which can give customers better mold solutions based on the analysis of products. If the products need laser welding, we can undertake a laser welding service to complete our one-stop mold processing services for our customers.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds