The brief introduction of IML process

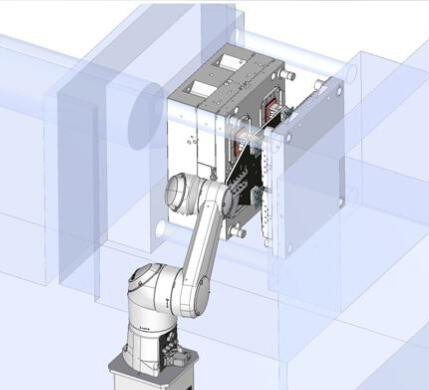

The technology “in mold labeling”(IML)is a kind of molding technique, the working principle is to place a preprinted label which has the pattern of the end product inside the mold, and the melted plastic mixed with PP label inside the mold, a stable, beautiful IML product will be ready for collect after injection.

The main advantages of IML molding:

High standard of print quality

The ink of the design is covered by a film on the product surface, and the design will not scratched by other objects, and it will last longer in a beautiful state.

Strong and healthy

As we mentioned previously, the ink is between the plastic and film, it will leak, so it is the best options for frozen products, such as ice creams and butter.

Shorter production cycle and lower costs

The products you get from the IML mold is the final product you expect, and no labeling process is needed, all the production and decoration will be finished together.

Eco friendly

IML molding saves lots of energy on secondary labeling process, and the production and decoration uses same material, which means the product recycling will be easy.

IML technology now is the best option for food related company, especially for the dairy food company. The high quality decoration and excellent look makes this technology spreads fast over the world. If you need any support of IML molds, you can contact us.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds