The cooling methods of the die casting mold

In the production of die casting products, the die casting machine will generate heavy heat for melting material and inject them into the cavity for target products, after cooling, the products will be ready for collection. Most of the heat will transfer from the molten material into the mold, the heavy heat will influence the product quality and service life of the mold. To better solve the cooling issue, we need to apply suitable cooling methods to the die casting mold to ensure the temperature of the mold is under a reasonable range.

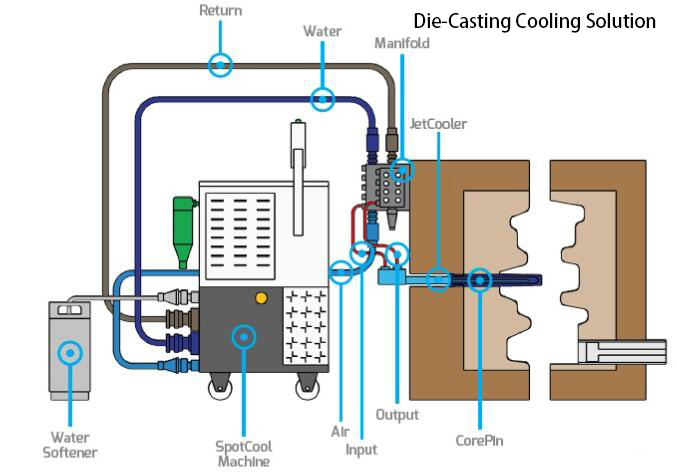

Some cooling methods for die casting mold: extend the casting cycle, spray release agent on the cavity and use cooling water. Among them, the application of a cooling water system is the most effective way.

When using water as a cooling medium to cool the mold, we can connect the mold directly with the water or through a professional chiller. The main difference between these two is that the temperature control provided by the chiller is more accurate, and the stability is higher. If the water is connected with the mold directly, the temperature difference between the water and mold will be sharp. This system will easily affect the product quality and service life, such as the small cracks in the cavity.

As a professional die casting mold supplier, we will design the die casting mold with a fixed point cooling structure based on the circulating water. This cooling system has a simple structure, low cost in production and maintenance, also the cooling position can be adjusted at any time to make the product perfect.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds