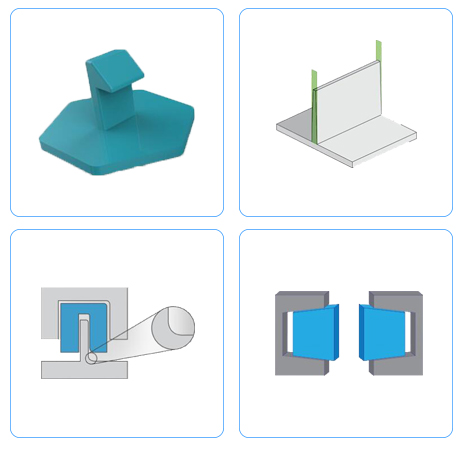

The four common mistakes for plastic parts designing

Molded parts are products obtained by injection molten plastic under high pressure and speed provided by injection machine after cooling. Injection molding is a complex process, and the product design is the key part of the whole process. A small design issues may cause serious quality problems in molding process. Here are four of the most common design issues in product design.

1. Undercuts

An undercut with small dimensions can be solved by forced demolding. But if the size of the undercut is large, it needs to be redesigned to avoid quality problems in the coming process.

2. Non-uniform wall thickness

A uniform wall thickness ensures that the molten plastic fills the mold cavity precisely without sink marks on product surface. In areas with thicker design, we can remove the plastic by use coring and ribbing methods.

3. Draft angle

The purpose of draft angle is to improve the efficiency of product demolding. If the product has no draft angle or the angle is slightly small, this product may stick to the mold in the process. We should consider the shrinkage rate of the material and function of the parts to set a suitable draft angle for the products. In general, the draft angle can be around 1.5 to 2 degrees.

4. Sharp corners

Injection products should avoid the design of sharp corner, because filling sharp corners requires high injection pressure, which means higher processing costs, and some small internal sharp corners cannot be filled completely by injection molding.

Shanghai Future Mould has professional mold engineers who can assist customer to review product design and modify the design if necessary

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds