The introduction of the shrinkage and tolerance

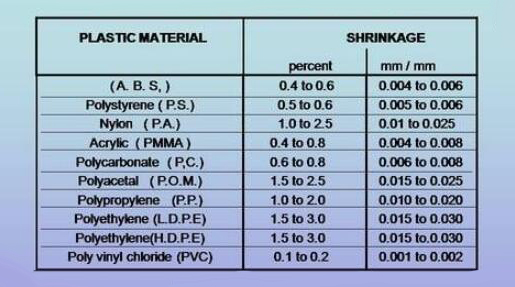

When the engineer starts designing the injection mold, they need to determine the mold structure first, and then to choose the right size of the mold accessories, mold core in detail. On the processing of the injection mold, the shrinkage of the material must be fully considered, only the specific shrinkage rate of the raw material can determine the correct size of the cavity and related accessories.

The shrinkage of the plastic material

The characteristic of thermoplastic is that they expand after heating and shrink after cooling. In the injection process, the melted plastic fills into the cavity first with the press of the injection mold machine, after pressing, cooling, and demolding, it will shrink because of the temperature changes. Another situation is that for the plastic with hygroscopicity, during the injection process, the plastic parts will expand after contact with moisture.

In general, the shrinkage of the injection material is within a range, the change of the shrinkage rate usually depends on the shape of the product, and the mold structure and molding condition. When we determine the final set of these changeable conditions, the size and precision of the injection mold can be set more accurately.

The structure of the injection mold

The general gate form of the mold structure has a significant effect on shrinkage. The cooling system is the key point of the mold design. If the design is not reasonable, it will cause the temperature difference of each part and resulting in a shrinkage difference.

The mold size and tolerance

The engineers can calculate the precise size of the mold cavity and core before processing through the formula and it is necessary to combine the actual shrinkage range and product stability to get different shrinkage rates. At present, most of the countries in the world have formulated corresponding national standards of tolerance on plastic parts for lowering processing difficulty.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds