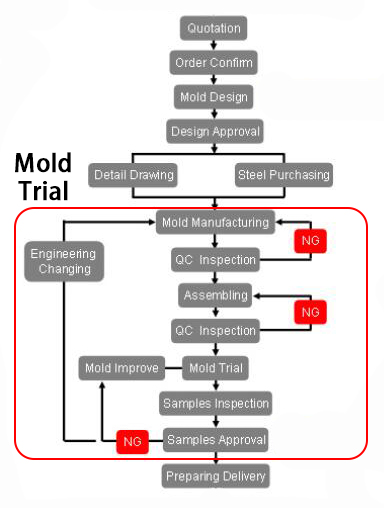

The main steps and methods of injection mold test

The mold trial is the most important part of the mold processing stage, and the result of the mold trial will directly affect the subsequent production and mold adjustment. Therefore, during the mold trail process, it is necessary to follow reasonable operation steps and record complete technical parameters, which is beneficial to the later adjustment of the mold.

To avoid spending too much time to verify the injection molding conditions during mass production, and it is necessary to find out the suitable processing conditions and related attributes from the beginning and formulate standard production steps, which is convenient for reference in later mass production.

The main steps of the injection mold trial:

1. Check whether the plastic in the barrel is correct.

2. Clean the material tube and check whether the temperature of the material tube and mold temperature is suitable for mass processing.

3. Adjust the pressure and injection volume of the injection machine to produce the finished product with a satisfactory appearance.

4. Wait patiently until the machine and mold stabilize, and use this time to check for possible problems of the finished product.

5. The time for the screw to advance should not be shorter than the time for the plastic neat the gate to solidify, otherwise, the weight of the finished product will be reduced and the performance of the product will be impaired.

6. Adjust parameters reasonably and reduce the production and processing cycle.

7. Measure the sample and record its weight and size.

8. Compare the size of each sample to determine whether the product size is stable, whether the size change is caused by the adjustment of the injection machine, and whether the size change is within the tolerance range.

9. Let the injection machine run for a longer time, stabilize the temperature of the plastic and hydraulic oil, and reduce the influence of temperature on the plastic parts.

10. Check the failure of the injection machine to eliminate product quality defects caused by the failure of the injection machine.

At present, it is easy to ignore the mold temperature and record the influence of the temperature of the mold in the mold trial process, thus to cause injection defects easily in subsequent mass production.

During the mold trial, follow the steps to record and adjust the various elements in the process, you can quickly find the source of the problem in the production, and adjust the mold and injection machine to get well-finish products.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds