The maintenance of injection mold

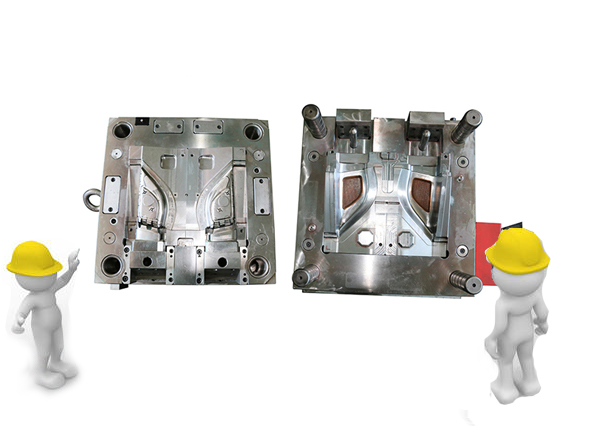

The injection molds are the tools for shaping the raw materials into a certain structure, and normally, the injection molds need to be replaced frequently or stocked after a period. During the period of the inventory, manufacturers often encounter problems such as rust and reduced surface finish, which will cause problems such as product quality degradation and serious defects on the product, sometimes, the manufacturers need to make another mold for daily production.

The injection molds are the tools for shaping the raw materials into a certain structure, and normally, the injection molds need to be replaced frequently or stocked after a period. During the period of the inventory, manufacturers often encounter problems such as rust and reduced surface finish, which will cause problems such as product quality degradation and serious defects on the product, sometimes, the manufacturers need to make another mold for daily production.

There are many factors causes mold corrosion, such as mold steel and the surrounding environment of the inventory warehouse, but the most serious reason is ignorance of mold maintenance. In general, after using, we must clean the mold surface and the residual material on the mold to keep the mold neat, and this step can ensure the good condition of the mold in the next production, and greatly reduce the probability of damage.

The main aspect of the maintenance of injection molds is to prevent corrosion. Generally, on this issue, mold holders can choose a suitable or professional anti-rust oil, and spread the oil on the mold surface to form a protective film, and this film can block the moisture in the air from contact with the mold surface. Besides, after completed the production task, by the actual structure of the mold, the remaining plastic in the mold cavity or other places in the mold should be taken out by a suitable tools, such as copper rods, copper wires, and it should be noted that, do not use sharp objects like wire to clean the mold cavity, as it may cause scratches on the mold surface. The warehouse that stock injection molds need to pay attention to daily ventilation to ensure airflow.

According to the data, normally the mold service life is 500,000 times, a well-maintained mold can reach even 1 million to 1.5million times, and these improperly maintained injection molds tend to have shorter lifespans, and manufacturers need to make new molds, which greatly prolongs the production cycle and increases production costs.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds