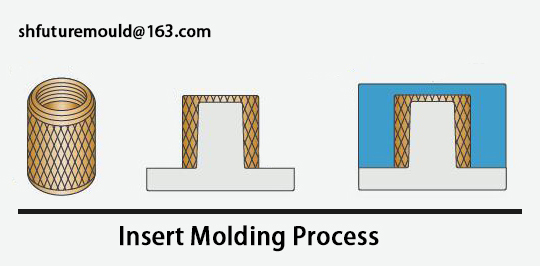

The process of insert molding

Insert molding refers to the processing that inserting pre-prepared inserts of different materials into the injection mold and joint with a resin material to form an integrated product.

The characteristics of inserting moldings are as follows:

1. The combination of the resin’s easy formability, bendability, and the strength, and the hardness of the metal can produce complex and exquisite integrated products.

2. For the production of the electric-related product, the insert molding is the best way to achieve the combination of these two different materials. The insulation properties of resins and the conductivity of metals can be fully utilized to provide the performance that satisfies the electrical products.

3. The insert molding can achieve multiple inserts simultaneously, making the product unit combination more reasonable and convenient.

4. There are many types of inserts, not just limited to metal, other materials like glass, coil, etc. can also be used as insert materials.

5. Compared with the press method, the gap of the metal inserts between resins can be designed to be narrower, and the reliability after molding is better.

6. To choose the appropriate mold, the inserts can be completely sealed inside the resin.

Some matters needing attention in the design of the insert molding system:

1. Metal insert molding is prone to problems with different molding shrinkage rates, and the shape and dimensional accuracy of important parts should be tested in advance.

2. During the injection molding process, if the metal inserts are easy to shake and move, the structure of the mold and the mold design should be fully considered to maintain the stability of the metal inserts.

3. The difficulty of restricting the mold structure design, such as the position of the mold gate and the molding cycle, should be solved as far as possible in advance or the feasible measures should be sorted out in advance.

4. It needs to confirm whether the metal inserts need preheating or drying, the purpose of these processes is to ensure the quality and molding stability.

5. The various detection elements provided in the mold should be prepared to ensure the stability of the mold in a certain condition. Before the injection molding starts, you should confirm whether it is necessary to use it.

Compared with the processing of ordinary plastic parts, injection molding has more difficulties and more complicated processes, but it also provides the feasibility of producing more types of products, and at the same time, it can ensure the stability of the products under these conditions.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds