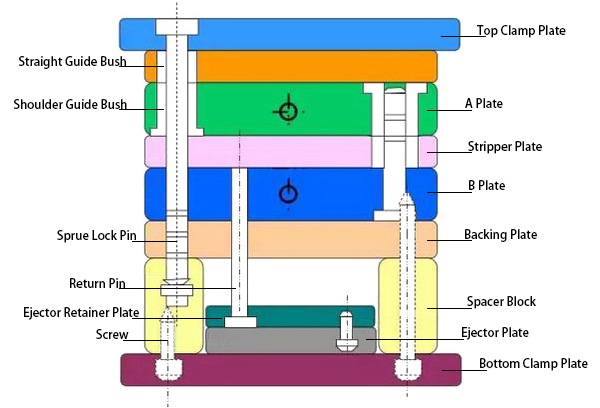

Three-plate mold

Generally speaking, from the same product, two-plate mold is better than three-plate mold in terms of mold size, structural strength, molding time, molding pressure, etc.. But three-plate mold has a clear advantage that is the product does not need to be trimmed. The existence of the three-plate mold is mainly due to the appearance and production requirements of the plastic product.

Generally speaking, from the same product, two-plate mold is better than three-plate mold in terms of mold size, structural strength, molding time, molding pressure, etc.. But three-plate mold has a clear advantage that is the product does not need to be trimmed. The existence of the three-plate mold is mainly due to the appearance and production requirements of the plastic product.

Three-plate mold has three sections (one between the runner plate and the cavity plate, the second between the runner plate and the top clamping plate, and the third between the cavity plate and the core plate), two parting surfaces. Compared with the two-plate mold, three-plate mold adds a gate plate, because three-plate mold uses a point gate, it is also called pin-point gate mold.

The demoulding sequence of the three-plate mold:

1. First, when the core is pulled by the injection molding machine, because there is a nylon lock between the core and the cavity plate, and there is no connection or constraint between the runner plate and the cavity plate. Under the action of the pulling force at this moment, the flow channel plate is first separated from the cavity plate, and then the cavity plate and the core plate are moved backward to a preset value distance.

2. The cavity plate continues to move backward through the injection molding machine, so that the small tie rods also move, which in turn drives the runner plate to a preset distance, thereby removing the gate and runner. After the preset distance is completed, the small lever and cavity plate stops moving.

3. The injection molding machine continues to move backward to increase the pulling force beyond the clamping force of the nylon lock, to separate the cavity plate from the core plate by a preset distance before stopping.

4. Driven by the ejector of the molding machine, the ejection plate drives the ejection system (ejector, sleeve, and lifter, etc.) to start ejecting the finished product (automatically or by mechanical arm removal).

5. Driven by the injection molding machine, the core moves to the cavity. If the top plate is not pulled back early, the return pin will first contact the cavity plate. Then under the action of the reaction force, the ejector plate returns through the reset pin.

6. Press the core plate on the cavity plate and the runner plate until the mold is tightly closed. The nozzle on the injection molding machine is in close contact with the nozzle bushing on the mold, preparing for the next molding cycle.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds