Under what situations should the hot runner be used?

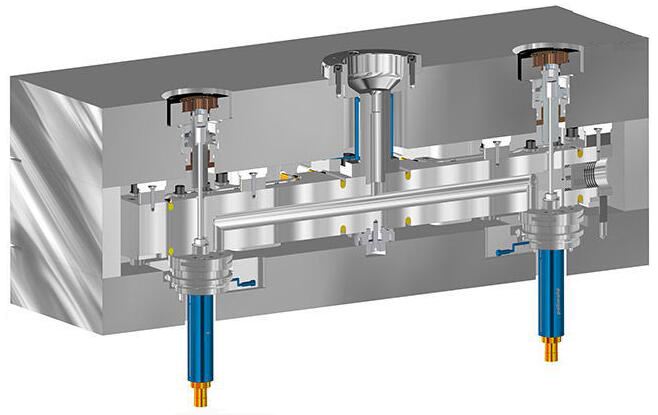

The hot runner system is a heating device used in injection molds to inject melt plastic into the mold cavity.

During the molding process of the hot runner mold, the temperature of the melted plastic in the runner can be effectively controlled, and there is no difference in the state of the plastic entering the cavity. Also, the gate part of the product produced by the hot runner system performs well, the internal stress of the product is low, and there will be no serious deformation issues of the product after cooling. At present, the main high standard products on the market are processed by hot runner mold, some world-class company also requires to use hot runners to produce their products. So, under what conditions should a hot runner system be used?

Large size products and thin-walled products.

Annual output requirement.

High appearance and precision requirements.

The runner in the mold is long.

Multi-cavity mold.

The hot runner system has good performance in the product molding cycle, waste recycling, and product dimensional accuracy. Customers can discuss with mold suppliers whether they need to use a hot runner system in the mold.

Shanghai Future Mould is a mold manufacturer who has been engaged in mold manufacturing for more than ten years, we have rich experience in both hot and cold runner molds, and can give customers the most authoritative instruction and suggestions, you can also specify the structure and brand of the hot runner according to your needs and budget. Welcome to consult.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds