What are the advantages of hot runner systems in injection mold?

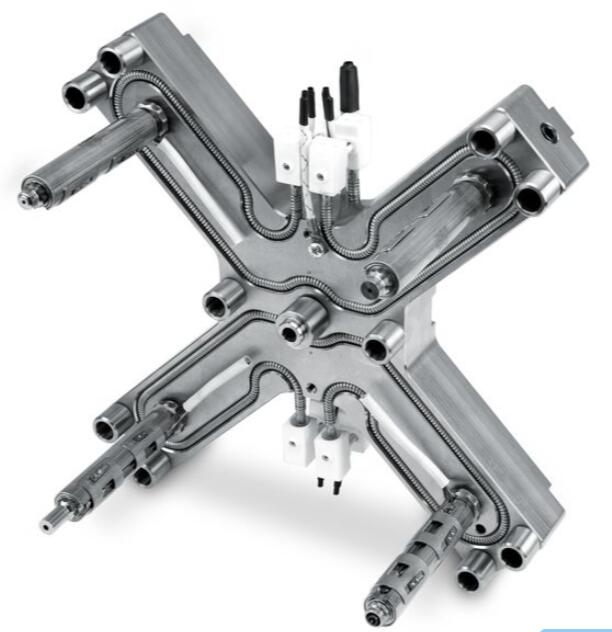

An injection mold hot runner system is a system that uses a heating system to keep the molten plastic at a constant temperature throughout the processing of injection from the injection molding machine to the mold cavity.

The injection mold hot runner system has the following advantages:

1. shorter cycle time. Hot runner molds do not require cold runners, so the cycle time can be shortened. For instance, the cycle time of one shot with a hot runner system for some thin-walled products can be shortened to less than 5 seconds.

2. Material saving. Hot runner molds do not have cold runners, so they can save materials. Cold runners produce waste in molding, and using hot runner molds can largely avoid the waste of materials.

3. Improved product quality. Hot runner molds can ensure that the molten plastic flows evenly into the mold cavity, thereby improving product quality. Hot runner mold can avoid gate marks, improving surface quality; Hot runner molds can reduce the probability of product deformation, improving production precision.

4. Favorable for production automation. Hot runner molds can reduce subsequent processes, which is beneficial for the automation of molding. For example, hot runner molds do not need to remove the gate from the mold, which can improve production efficiency.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds