What are the advantages of nitrogen-assisted molding technology?

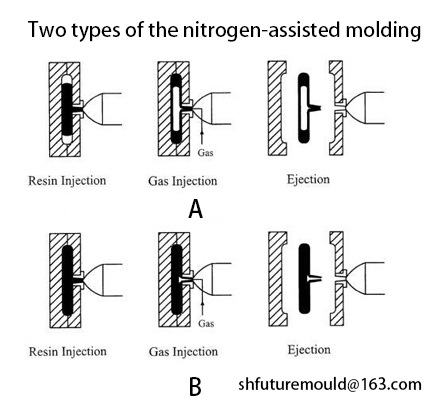

Nitrogen-assisted molding technology refers to injecting nitrogen directly into the melted plastic in the mold cavity through a segmented pressure control system so that the plastic parts expand with a smooth outer surface. The traditional injection molding process cannot produce plastic parts with both thick and thin walls, otherwise, it will cause defects such as internal stress and deformation. Nitrogen-assisted molding technology can produce this type of product with an excellent appearance. At present, nitrogen auxiliary devices include nitrogen generators and booster systems, pressure control units, and air intake components.

The application of nitrogen-assisted molding technology has the following advantages:

1. Save raw materials.

2. Shorten the product production cycle.

3. Reduce the clamping force of the injection molding machine.

4. Improve the service life of the injection molding machine.

5. Reduce the pressure in the cavity and increase the service life of the mold.

6. Aluminum material can be used as raw materials for mold manufacturing.

7. Reduce the internal stress of the product and eliminate the defect of product deformation.

8. Solve and eliminate the defect of product surface shrinkage.

9. Reduce mold manufacturing costs.

At present, nitrogen-assisted molding technology has been widely used in different industries, including automotive products, electrical products, and home appliances.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds