What are the applications of modified nylon in the injection molding process?

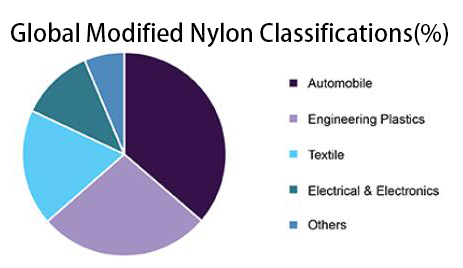

Nylon material is a common material in the plastic injection industry and it has been applying many traditional industries, like automotive, electrical appliances, and medical industries. At the same time, to further improve the material properties of PA material in different directions, we can add some modified material to the raw nylon to improve the injection properties of PA and improve the moisture absorption of PA.

Modified nylon material;

1. Flame-retardant PA

Adding flame-retardants to raw material can further improve the flame-retardant properties of nylon plastics and broaden the application of the material. During the injection molding process, it is necessary to check the injection temperature and mold temperature to prevent the flame-retardants from decomposing due to excessive temperature.

2. Weather-resistant PA

Adding carbon and other reagents to PA can improve the weather resistance of PA material. But the carbon regent can enhance the self-lubricity of PA material, which will aggravate the damage to the mold during the injection process.

3. Transparent PA

Transparent PA has good light transmittance, and also good impact resistance and surface hardness, similar to optical glass. In the molding process, the temperature of the barrel should be strictly controlled, the high temperature will cause color changes, thereby to affect the transparency of the products.

4. Glass fiber PA

Adding glass fiber into the PA can greatly improve the mechanical strength of the material. In the injection molding process, the injection pressure and injection speed should be appropriately increased to ensure the flow rate of the melted material. At the same time, the bimetal screw can be applied in the mold design to alleviate the mold abrasion.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds