What are the common parameters in the injection molding process?

The injection molding industry has now become the foundation of modern industry, providing a strong guarantee for different industries, such as automotive, medical, and home appliances. With the continuous development of various industries, their requirements upon the quality of plastic parts are also constantly improving, which also requires a steady molding process and high technical level to further ensure product quality.

To meet the demands of customers for plastic parts, it is necessary to continuously improve the technical capabilities of the equipment, and also to set the working parameters in the molding process to achieve high quality.

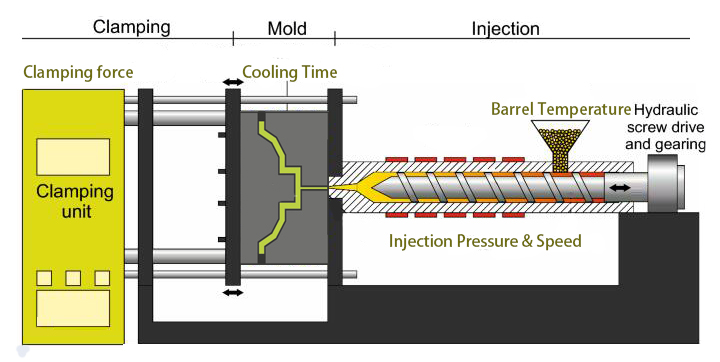

In the injection molding process, the parameters that need to be paid attention to are:

1. Clamping force

In the molding process, the adjustment of the clamping force also needs to consider factors such as mold expansion. The principle of setting the clamping force is to ensure the quality of the product.

2. Barrel temperature, mold temperature

Choose the suitable barrel temperature by the actual properties of different materials. The temperature of the barrel is generally 10-30℃ higher than the melting point of the material. It should be noted that the source of the material is another factor that influences the melting point of the raw material.

The mold temperature is generally controlled by circulating cooling water, but for products with precise dimensions or high-quality requirements, a mold temperature controller should be adopted by the actual needs.

3. Holing time, cooling time.

Injection time, holding time, and cooling time must be set by product thickness, mold temperature, and material properties.

4. Injection pressure and speed

Under the premise of ensuring sufficient injection power, the injection pressure should be as low as possible. For products with higher requirements, we should adopt higher injection speeds to ensure smooth demolding.

To control the quality of plastic parts requires a high-precision injection molding machine, also reasonable parameter setting. To know the content of each parameter for the molding process is an indispensable step in the molding industry.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds