What are the functions of chrome plating on the cavity surface?

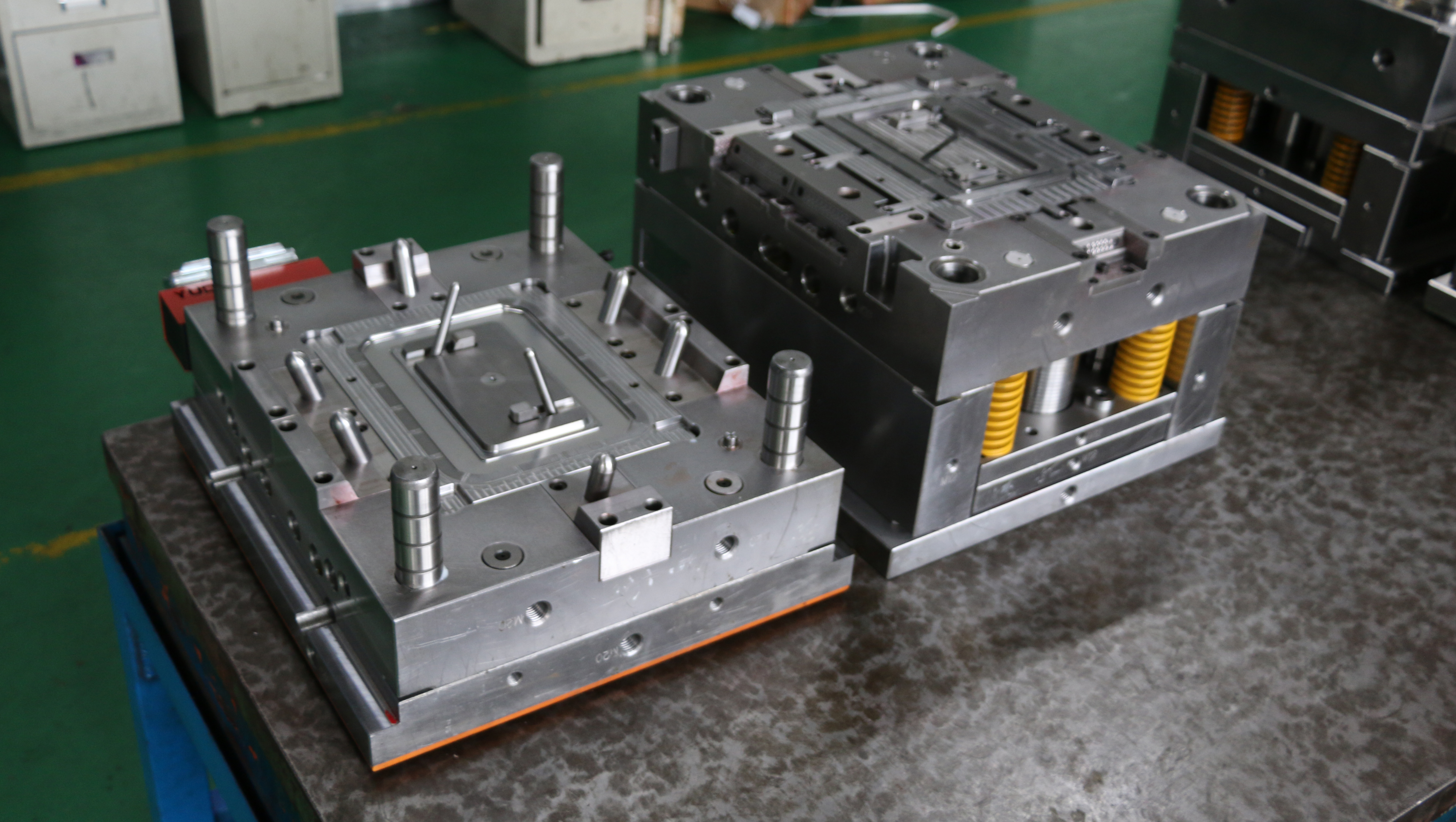

In the project, many methods can be used to improve the surface quality of the mold and product, such as polishing, electroplating, texture, etc. These methods are also known as the technologies of mold surface treatment. Today we will focus on electroplating for mold cavity.

The main purpose of mold cavity electroplating is to improve the flatness and to ensure that the product can eject out from mold easily. Of course, electroplating can prevent the surface from rusting, thereby improve the surface quality of the plastic parts. Also, electroplating can improve the hardness of the mold, as well as its temperature resistance, corrosion resistance, and wear resistance, which means the service life of the mold will be greatly extended.

Electroplating on the mold cavity is one of the effective ways to improve the mold and product quality, we must strictly inspect the plating quality to ensure that there are no defects exists on the chrome layer. Shanghai Future Mould is a mold manufacturer with rich experience in mold electroplating and can provide customers with praiseworthy injection molds. We are here for you.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds