What are the functions of reinforcing ribs in injection products?

The function of reinforcing robs in injection products is to improve the structural strength of the plastic product, prevent deformation during the production process and transportation, and at the same time, will not cause defects such as sink marks. Reinforcing ribs are the best ways to improve product strength currently, and it can improve product quality and effectively reduce the costs of production.

Reinforcing ribs can set at a suitable position of the product with the remained wall thickness to ensure structural strength. Reinforcing ribs can avoid product deformation and improve its rigidity. Also, it can act as an internal flow channel to improve the flowing of melted plastic during the molding process.

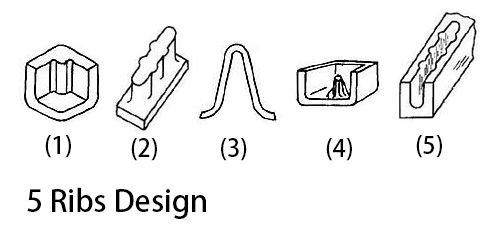

At present, the reinforcing ribs that can be used in the injection products include long strips, fan-shape, and circle types. Strip reinforcing ribs are generally used on injection products that do not need to carry the high-strength load, and the area where the reinforcing ribs can be set is small. If the center part of the product shell has a strong stress point, it is more appropriate to design circular or fan-shaped ribs.

The height setting of the reinforcing ribs needs to be designed reasonably according to the actual needs of the product. In the case of reaching the required strength of the product, the lower, the better, if the height of the reinforcing rib is too high, demolding problems and the strength problems of the reinforcing ribs will occur in the molding process.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds