What are the issues regarding the hardness of TPE in Injection molding?

Thermoplastic elastomer TPE, commonly known as synthetic rubber, has excellent properties such as aging resistance and high elasticity. It has superior processing performance and can be processed by injection molding, extrusion, blow molding, etc.

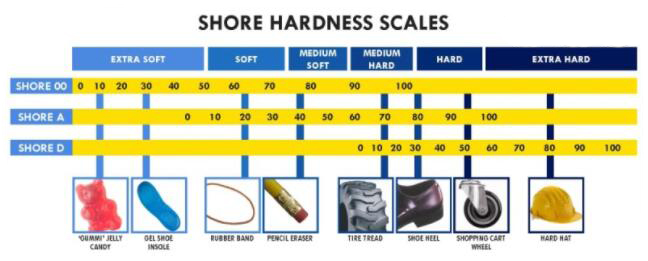

The hardness range of TPE is from 0A-100A. The test standard here we use is Shore A hardness, also, there are has two test standards, Shore C and Shore D, but Shore A is the common one.

As we all know, the hardness of plastic materials has a greater impact on the molding. The harder material means that more demolding methods can be used, such as ejector pin and plate. On the contrary, if the material is soft, we cannot proceed with the conventional demolding method, and how to solve these problems?

First, we should choose the suitable hardness of TPE by its functional and appearance requirements of the product. If the lower hardness TPE is needed, we can modify the design to create a small angle of demolding slope, or use a demolding agent to assist, and then cooperate with the ejector plate and other mechanisms for support.

Shanghai Future Mould is an ISO-certificated professional mold manufacturer, our company has professional technicians who can solve the issues of TPE products with different hardness, you can contact us for technical support.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds