What are the key points of ejector pin design in the injection mold?

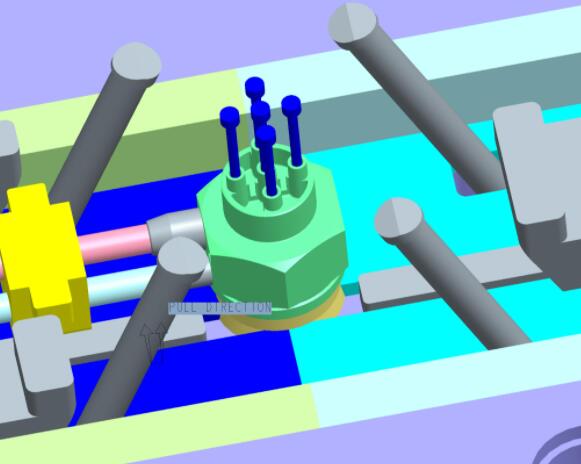

The ejection system in the mold includes: ejector pin, push plate, cylinder, lift, etc. For different products, we can choose the suitable ejection system for demolding by the actual structures.

The ejector pin is the most common method in the ejection system, it has many advantages in operation, such as simple processing, easy installation, convenient maintenance, so it is currently one of the most extensive ejection measures. On the contrary, some tips need to be mentioned on the pin-type ejection system. The contact area between the pin and the product is small, which means unreasonable design on ejector pin location will cause serious quality issues of products, especially for those parts which have higher appearance requirements and thin-wall structure.

At present, there are different standards on ejector pin used in the injection mold worldwide, European customers generally adopt the HASCO standard, The United States takes DME standard, and Japan allows MISUMI standard, so we should check with customers about their standard required before we start to manufacture. The installation of the ejector pin in the assembly stage should strictly follow the instruction given by the suppliers to ensure that the ejector pin can work normally in the molding process.

Shanghai Future Mould is a leading injection mold manufacture, and we have established cooperation with many worldwide companies and provide them professional molds and qualified products. We can provide our customers the most economical mold design and ejector system suggestions based on their needs.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds