What are the main structures of the injection molding machine?

Injection molding machine consists of an injection system, clamping system, hydraulic transmission system, electrical control system, lubrication system, and safety monitoring system.

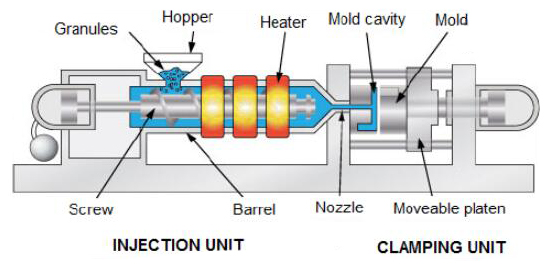

1. Injection system: the injection system is the most important part of the injection machine. Its function is to inject the melted plastic into the mold cavity at the required pressure and speed. The composition of the injection system includes a plasticization device and power transmission device.

The plasticization device of the screw injection molding machine is mainly composed of a feeding device, feed barrel, etc. The power transmission device includes an injection cylinder, a driving device, etc.

2. Mold clamping system: the function of the mold clamping system is to ensure the opening, closing of the injection mold, and the ejection operation, and to ensure that there are no gaps between the mold during the injection molding process and to prevent such defects as flashes.

The composition of the mold clamping system includes a mold clamping device, ejection mechanism, safety protection mechanism, etc.

3. Hydraulic system: the function of the hydraulic system is to provide the working power required in the injection molding process and to meet the pressure and working temperature required by the auxiliary mechanism of the injection machine. It is mainly composed of hydraulic components and auxiliary elements. The oil pump and motor are the power source of the injection machine, and we can achieve power control by adjusting the oil pressure and flowing speed.

4. Electrical system: the electrical system needs to cooperate with the hydraulic system to provide the pressure, temperature, and other power required by the injection molding process. It mainly consists of electrical appliances, electrical meters, and other support components. From the control method, it can divide into automatic, manual, etc.

5. Lubrication system: the lubrication system is a structure that provides lubricates for the movable parts of the injection machine. The main purpose is to reduce energy consumption and extend the service life of the injection machine.

6. Safety monitoring system: the safety monitoring system in the injection machine is used to protect the machine operator and the machine. It is mainly composed of safety doors, hydraulic valves, detection components, etc.

The monitoring system in the injection machine mainly checks the oil temperature and material temperature of the injection machine. If something wrong in the injection machine, it will trigger the alarm to remind the technicians.