What are the polishing methods for injection molds?

In the process of mold manufacturing, the mold surface can be ground and polished to get a smoother plastic product, which is also an important process to improve the quality of the molds and plastic parts.

1. The common methods of polishing

1. Mechanical polishing

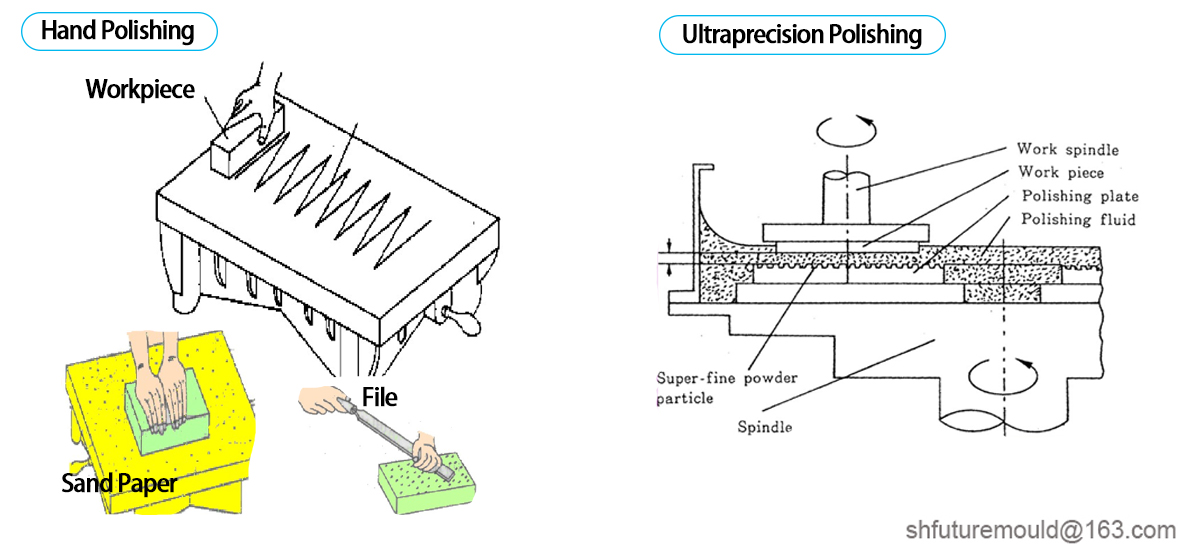

The mechanical polishing is a polishing method that removes protrusions on the surface by cutting or deforming the surface, and generally, oilstones and sandpaper can be used as the tools, and mechanical polishing is mainly achieved by manual.

For molds with high surface requirements, we can adopt the super-precision grinding method, super-precision grinding is a special method of polishing, mainly uses grinding fluid to do the high-speed optional movement on the surface.

2. Chemical polishing

The chemical polishing is a polishing method that dissolves the protrusions on the mold surface by the different chemical medium. The chemical polishing can be polishing the workpieces with complex shapes and achieve the process with high efficiency.

3. Electrolytic polishing

The working principle of electrolytic polishing is the same as chemical polishing. The advantage of electrolytic polishing is that it can eliminate the influence of the cathode reaction.

4. Ultrasonic polishing

The ultrasonic polishing is a polishing method that uses the ultrasonic vibration of the cross-section of the mold to polish through the abrasive suspension, sink the workpiece into the abrasive suspension, and put the whole part into the ultrasonic field to achieve the polishing target by ultrasonic vibration.

5. Fluid polishing

The fluid polishing method relies on the flowing liquid and the abrasive particles it carries to wash the surface of the molds to achieve the purpose of polishing.

2. The common tools in the polishing

The common tools in the polishing are sandpaper, oilstones, abrasive suspension, files, and sander, etc.

3. The working environment of polishing

The polishing process should be completed separately at two locations, the rough grinding processing, and the fine grinding processing, also the dust and wastes should be removed from the previous process.

After the polishing process is completed, the surface of the mold should be protected from dust, and all the abrasive and lubricants should be carefully removed to ensure the cleanliness of the mold surface.

4. The main factors affecting surface polishing

1. The surface conditions of the mold

During the mechanical processing of the mold, the surface layer will be damaged easily due to heat, internal stress, and other factors, which will easily affect the whole polishing process.

2. The quality of the mold steel

The high-quality steel is a prerequisite for good polishing quality, and the debris and pores in the steel will affect the polishing process. Before polishing, the polishing surface roughness should be marked first.

3. The heat treatment process

If the hart treatment is improper, the hardness of the steel surface will be uneven, and it will bring more difficulty in the polishing process.

4. The polishing technology

Proficiency in polishing technology is an important factor affecting the polishing quality.