What are the precautions for choosing the right thickness of the plastic case?

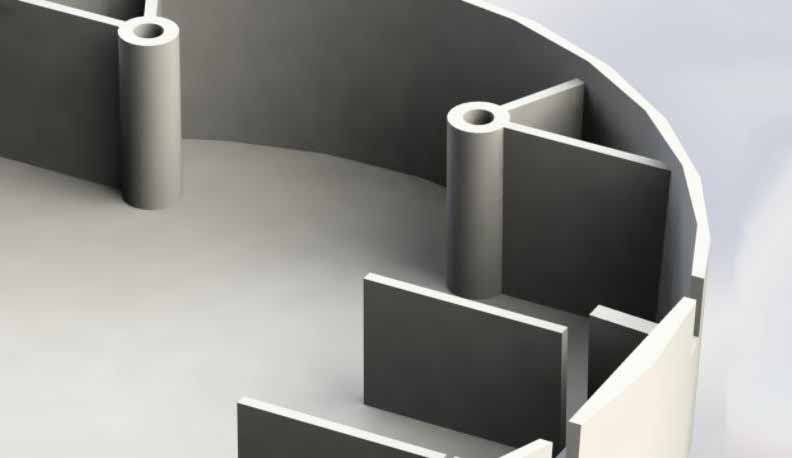

The wall thickness of the plastic cases is usually about 0.80-3.00mm. If the wall thickness is too thick, it is easy to cause defects such as shrinkage and bubbles. On the contrary, it will cause deformation and a short shot. It is not difficult for you to find that the thickness of the plastic products is basically between 1mm and 3mm, and the wall thickness of the entire product is uniform. Do you know why?

Firstly, choosing the right wall thickness for a plastic product can reduce the cost of the product and improve the quality, As I mentioned above, if the wall thickness of the product is too large, it is easy to have injection defects in the molding stage; at the same time, it will affect the cooling effect of the product and severely causing defects.

Secondly, a uniform wall thickness can ensure that the cooling efficiency of the product becomes higher, which is conducive to the coming demolding process.

When designing a plastic case, it is necessary to choose the required wall thickness of the product by the actual needs, such as whether strong mechanical strength is required to support other components in the case. For large products, we can relatively increase the product wall thickness to improve its mechanical strength; for smaller products, we can select a thin wall thickness to prevent sink marks and other defects.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds