What are the precautions in transparent parts processing?

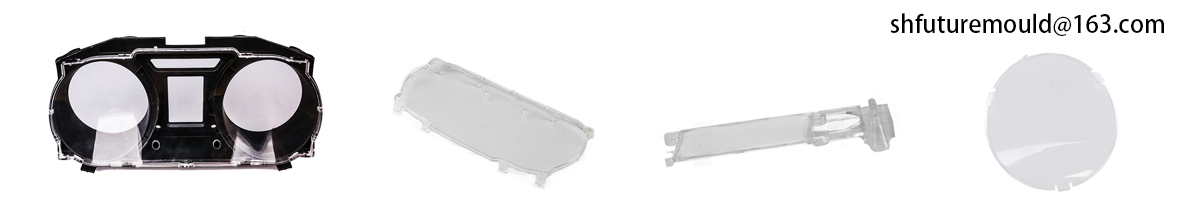

One of the characteristics of transparent products is its high light transmittance, this characteristic also requires a high-quality standard on the surface finishing of the product, also defects like streaks, pores, and black holes cannot appear on the surface of the product.

To eliminate the defects that may affect the product quality during the injection processing. Firstly, the raw materials, equipment, molds need to be strictly inspected during the entire injection process, secondly, due to the high melting point and poor fluidity of the raw material, to ensure the stability of injection, the process parameters of the injection machine need to be adjusted accordingly to ensure that the molten plastic can fill the cavity quickly and to avoid internal stress of the product.

1. The preparation and drying of raw materials

The impurities inside the raw materials will be the main reason for the color difference of products, therefore, in the process of material preparation, storage, transportation, and feeding, workers should ensure that the raw materials are clean and tidy. The moisture content in the raw materials will also affect the quality of transparent products. Under high temperature, the raw materials will deteriorate, so before the injection starts, the raw materials need to be dried at a certain temperature and for a certain period. 1. Choice different drying temperatures for different materials, 2.use dry air in the process.

2. The cleaning of the injection machine and other equipment

Some materials or impurities may accumulate in the screw or other places in the machine, and in the molding, these materials and impurities will be melted and mixed with the clean raw material for causing defects. Therefore, before injection, we should check various positions of the injection machine and remove the dirt.

3. Using suitable parameter settings according to the material, while ensuring the transparency of plastic parts, and it should reduce the possibilities of such defects caused by other reasons.

Transparent products, as a high-quality product in the injection mold industry, many small defects may cause irreversible damage to the entire process, therefore, we need to pay more attention to every aspect of the whole injection process.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds