What are the problems that are easy to overlook in the maintenance of the injection molds?

The injection molds need to be checked and maintained regularly after the injection molding process. Generally, the maintenance of each structure on the injection mold depends on the degree of abrasion during the molding process. The following suggestions are remarkable for mold repair and can decrease the probability of breakdowns of injection molds.

1. Check whether there is moisture or rust at the exhaust vent. If the inspector finds rust or moisture at the exhaust vent of the hot runner, and it means that the internal water pipe may be damaged.

2. Check the resistance value of the heater. After a period of injection molding, we should check the resistance value of the heater and compare it with before. If the resistance value fluctuates by about 10%, it means we need to replace the heater to ensure production safety in time.

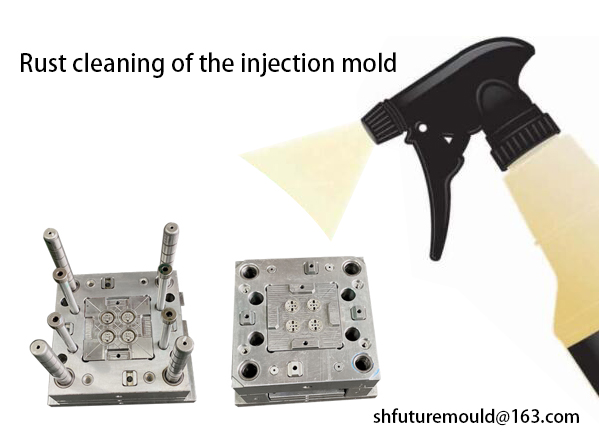

3. Check the abrasion between the guide rod and the sleeve. The inspect can evaluate the abrasion degree by the scratches between the guide rod and sleeve. If the abrasion is serious, we need to change this part. Otherwise, the mold cavity and core will not fit well in the later production.

4. Check the rust and blockage in the cooling pipe.

5. Clean the ejector pin. After a long period of the molding process, the tip of the ejector pin will accumulate many impurities. At this time, we should clean the ejector pin and apply lubricant on the ejector pin to prevent breakage.

To extend the service life of the injection mold as long as possible, we must pay attention to the working conditions of the injection mold, and we should proceed with the regular check on the injection mold to prevent irreversible damages.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds