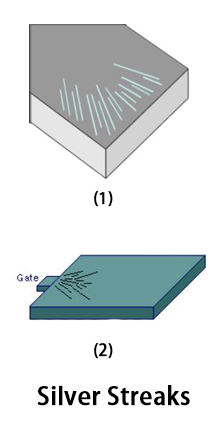

What are the reasons for silver streak defects in injection molding?

What are the reasons for silver streak defects in injection molding?

In injection molding, silver streak defects are mainly caused by incomplete drying of raw materials. When there are silver streaks on the injection product, we should dry the material fully to check whether it is caused by the raw material. If it is not, we can check from the following aspects.

1. Injection molding machine

(1) The barrel and screw of the injection molding machine are worn too seriously

(2) The heating system is out of control, causing the temperature of the injection molding machine to be high; improper screw design of the injection molding machine causes insufficient exhaust.

2. Injection mold

(1) Improper mold exhaust system

(2) The friction resistance of the runners, gates in the mold is large, causing the overheating problem.

(3) Unbalanced distribution of gates and cavities and unbalanced heating caused by unreasonable mold cooling system.

(4) The size of the runner and gate is too small or the length is too long, causing the melted plastic to condense in advance.

3. Injection molding process

(1) If the temperature, pressure, and injection speed of the injection molding machine are too high, it will cause decomposition of the raw material in the molding process. When the pressure and injection speed of the injection molding machine is too low, the material density will be insufficient and the gas inside the cavity cannot be dissolved completely.

(2) If you use release agents in the demolding stage, try to reduce the amount.

(3) If the material temperature is too low or the mold temperature is too low, it will affect the material flow rate and molding pressure, and then cause silver streak defects on the plastic parts.

4. Plastic materials

(1) The material has high humidity and the proportion of recycled material is too much.

(2) The material absorbs moisture severely or absorbs moisture from the colorant.

(3) The amount of lubricant, stabilizer, added to the plastic material is too much, or the mixing is uneven.

(4) There are impurities in the raw material.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds