What are the solutions to the sink marks of injection molded products?

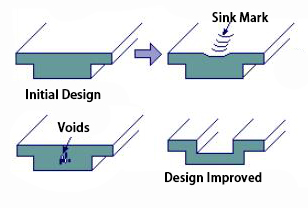

The shrinkage of plastic parts is the defect that caused by insufficient material replenishment at the thicker part when cooling. In general, we can solve it by adjusting the injection pressure or extending the injection period, but in some cases, we cannot conquer it by the above methods.

To ensure the quality of the plastic parts, the engineer have found some other effective solutions through the accumulation of long-term working and experience. We can better solve most of the difficulties with these solutions and parameter setting of the injection machine.

1. Shorten the cooling time. This method requires that the molded part be ejected at a higher temperature with the shape fixed. In this case, the temperature of the outer layer is higher and the surface is not over-hardened, so the temperature difference between the inside and outside of the molded parts is small, which is better on reduces the shrinkage, therefore to reduce the shrinkage on the surface of the plastic parts.

2. The concave occurs mainly because the mold surfaces heats up and the cooling capacity decreases. The surface of the parts after solidification is still soft, so the internal sink mark will be press by the pressure to form concaves. In the above method, after the plastic parts is taken out from the mold, it must be properly cooled to keep the surface of the product strong, so that no concaves will be occurs. Is the shrinkage problem is more serious, it is necessary to use frozen water to quickly cool the surface of the product to effectively prevent the shrinkage phenomenon, at the same time, we can adopt the method of extending the injection time to further improve the surface shrinkage problem.

3. In general, the above solutions may not completely solve the shrinkage problems, if needed, we can use anti-shrinkage agent appropriately to improve the product quality.

4. Gas-assisted injection molding is currently a relatively advanced plastic molding technology, which can eliminate product shrinkage through high-pressure gas. The gas-assisted injection molding device generally includes a nitrogen generation and booster system, a pressure control unit and an air inlet system.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds