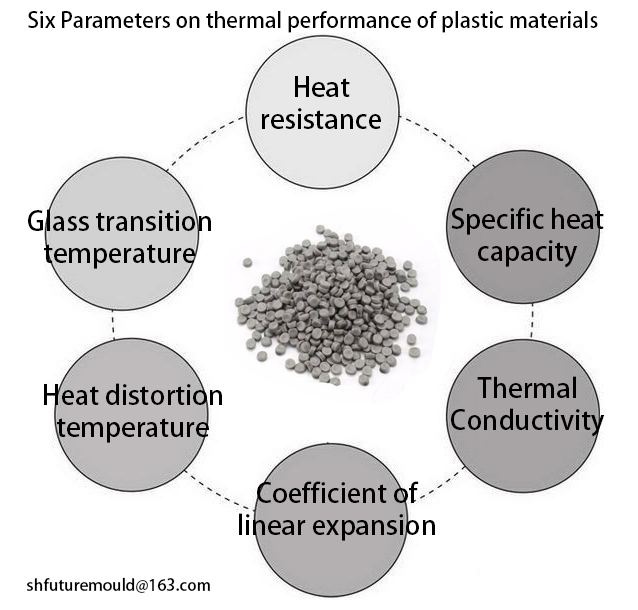

What are the thermal performance parameters of plastic materials?

1. Heat resistance

The heat resistance of plastic products can be divided into physical heat resistance and chemical heat resistance. The former refers to the performance of maintaining the shape of the product at a specified heating temperature, and the latter refers to the thermal stability of the molecular bonds in the plastic materials.

2. Glass transition temperature

When the temperature is higher than Tg, the amorphous polymer will become soft. To obtain the desired mechanical properties we should ensure that the temperature of the amorphous polymer is lower than Tg.

3. Heat distortion temperature

The heat distortion temperature is a method to determine the rigidity of plastic materials at high temperatures.

4. Coefficient of linear expansion

The coefficient of linear expansion refers to the expansion ratio of a plastic product when the temperature rises by 1℃ at a certain pressure, knowing as the coefficient of linear expansion per unit length. The coefficient is one of the important parameters to understand the degree of product dimension change as the temperature of plastic products increases.

5. Thermal Conductivity

The thermal conductivity represents the heat passing through a plastic product with a temperature difference of 1℃ and a thickness of 1cm within 1 second, and it is an important reference index in the product design stage.

6. Specific heat capacity

The specific heat capacity refers to the heat capacity relative to the unit mass of the plastic product. Generally, it means the heat required for plastic products to increase by 1℃. The specific heat capacity is one of the reference data for the product temperature change in the product design process.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds