What is an undercut structure? and how to solve it?

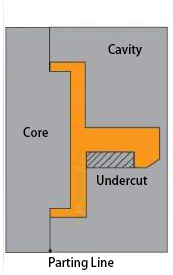

The undercut has always been an important structure issue in mold design and manufacture, so what exactly is undercut structure? The undercut can be defined as the structure that influences the ejection process, and the number of undercuts directly affects the costs of the mold, as well as the normal demolding process.

In some products, the undercut structure is necessary, for instance, threads and some button caps. For these cases, we need to use reasonable methods in mold design to ensure that the undercut structure can be well solved.

Some solutions on undercut structure:

1. Parting line: the mold engineer can adjust the draft angle by moving the parting line to prevent the undercut structure from affecting the demolding of the products.

2. Slider: the slider is one of the best methods to solve the problem of undercuts. After the product is cooled, the slider moves out and allowing the product to be ejected freely.

3. Lifter: the lifter is a component that can be ejected from the product with a set angle. When the product and lifter completely leave the mold, the product can be taken out smoothly.

If you have questions about product undercuts or other issues, you can contact us at any time for discussion, and we can work together to come up with the best solutions on mold and product solutions.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds