What is the basic knowledge of the mold ejection system?

The injection system is a structure that smoothly ejects the plastic product from the mold, also known as the ejection mechanism. The demolding process is the last step of the whole injection molding process, and the effect of demolding determines the product quality. When the mold is opening, the plastic product must remain on the side with a demolding structure, and the product will be pushed out by using the demolding mechanism in the mold structure.

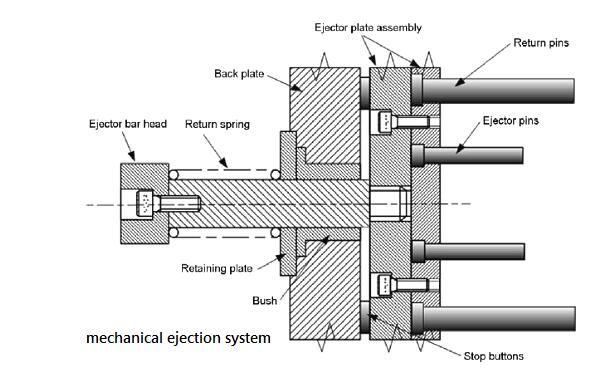

The composition of the mold ejection system

The ejection system generally includes upper and lower ejection plates, back stitches, return springs, and ejector pins, etc.

The demolding design principles

1. To ensure the stability of product quality during the demolding process, the ejector pins in the demolding structure should be arranged as uniform as possible and as close as possible to the part that is difficult to demolding on the plastic part.

2. The ejection structure should act on the part with higher structural strength in the plastic product and avoid working on the thin wall place.

3. The demolding position should be set on the non-appearance surface of the plastic product so as not to leave defects on the product, especially for transparent products.

4. The demolding mechanism in the injection mold should operate flexible and reliably, with sufficient structural strength and wear resistance.

Demolding method of plastic products

1. At present, the demolding methods of products include ejector pin, ejector sleeve, and partial ejector pin, etc. The price of the ejector sleeve and the partial ejector pin is too high, and the ejection mechanism of the push plate is mostly used in products with thin walls, so the ejector pin is the most common type of ejector method in the current mold industry.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds