What is the forced demolding structure?

When design the mold, the engineers will adapt a reasonable demolding structure for the mold according to its structure and to improve the efficiency of the mold in molding process. The common demolding structure include: manual, mechanical, etc. and normally they were achieved by ejector pins and plates.

For product with undercut structure, how should we design the demolding structure? Undercut structure is one of the toughest factors that influence mold structure. The undercut makes the injection mold unable to complete the molding process smoothly with the assistance of the lifers and slides, which is why when we meet undercuts, we will modify the structure first to remove the undercuts. Moreover, does it means we cannot achieve the products with undercuts by injection molding?

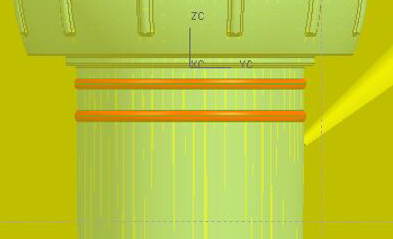

Now we will introduce you another demolding method which is called forced demolding mechanism. Forced demolding is not that difficult to understand from its meaning: that is, the plastic part will be ejected from the mold cavity by external force generated by injection machine. For forced demolding, the depth of the undercut and the area of the undercut are restricted, and the depth is about 0.2-0.3mm higher than the surface. At the same time, the forced demolding structure has certain requirements for the product material which can be PE,PP,ABS, etc. these material has better elastic to avoid the structure deformation in the demolding process.

Forced demolding process is one of the popular methods used by engineers to solve the undercut problem, and it is also the most effective way. Our company, Shanghai Future Mould is also a professional injection mold manufacturer in solving undercut product from different ways, such as structure reviews, forced demolding, etc.

- Injection Mold

- Automotive Injection Mold

- Electronics & Electrical Injection Mold

- Consumer Goods Injection Mold

- Airplane Components Injection Mold

- Medical Components Injection Mold

- Irrigation Components Injection Mold

- Injection Molds